AIMPLAS assesses the risks of reusable packaging for foodstuffs

The project is financed under the IVACE+i program, in collaboration with technology centers in the Valencian Community, and with support from the European Union's ERDF.

The project is financed under the IVACE+i program, in collaboration with technology centers in the Valencian Community, and with support from the European Union's ERDF.

The floating system generates hydrogen using only dissolved plastic bottles and direct sunlight, and works even in seawater.

The MIT panel produced potable water in the desert without requiring electricity or solar panels.

The modular approach will make it possible to scale quantum systems more efficiently and ensure fault tolerance in real-world situations.

The system was able to reduce ammonia by 99% without using electricity or chemicals.

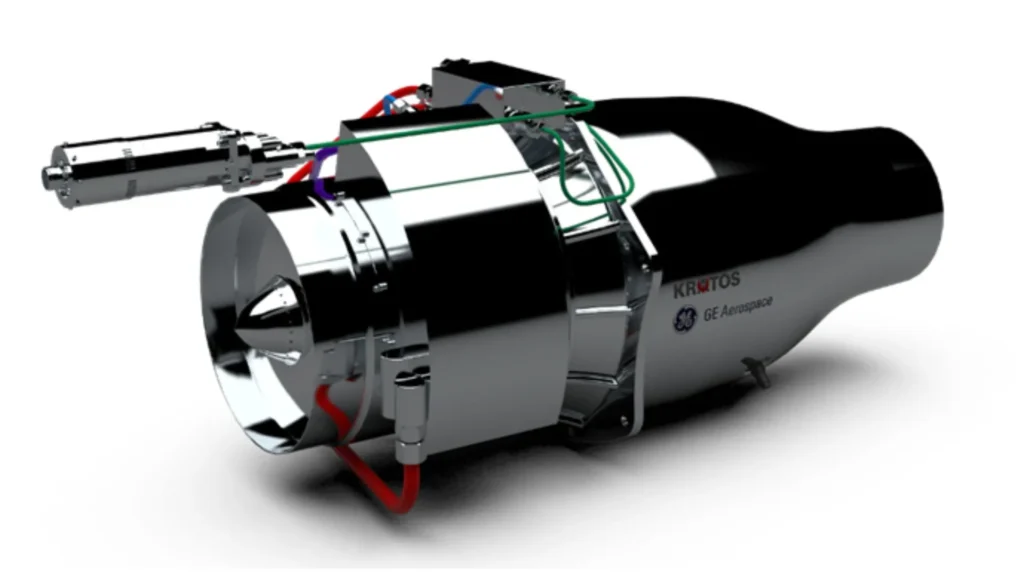

This agreement contemplates future collaboration on additional product lines, establishing an alliance in the air defense sector.

The reduction in capture time achieves improved possibilities for automating processes that previously required human supervision or manual adjustments.

MIT analyzed more than one million mineral samples with AI to identify recyclable materials to replace cement.

The machine converts 10 kg of CO₂ from the air into 4 liters of gasoline per day.

They used infrared light to scan objects, but captured the image with visible interlaced photons.

The joint objective of this initiative is to generate viable solutions for the market that contribute to cleaner cities.

The mission of this AI Technology Center will be to promote applied research and specialized training in the Swedish country.