Safety culture at liquid terminals

In and liquid terminals, safety culture is the backbone of operational excellence. Small oversights cause catastrophic accidents.

He has more than 40 years in the oil and gas industry and is an expert in Level I Ultrasonic maintenance and inspection. His commitment to excellence ensures the reliability of critical equipment. He stands out for his vast experience, comprehensive understanding of methodologies and adaptability to new technologies.

In and liquid terminals, safety culture is the backbone of operational excellence. Small oversights cause catastrophic accidents.

Optimize the inspection of complex surfaces and critical components with laser thermography, robotic systems and infrared sensors for accurate results.

Operational modal analysis (OMA) has become a pivotal tool in the evolution of structural health monitoring, asset reliability, and predictive maintenance strategies.

Ensuring tank safety by complying with NFPA 30 in design and operation.

Exploring how artificial intelligence and machine learning optimize operational risk assessment in oil and gas.

FPSO vessels have emerged as a distinctive alternative to fixed platforms and other traditional offshore systems.

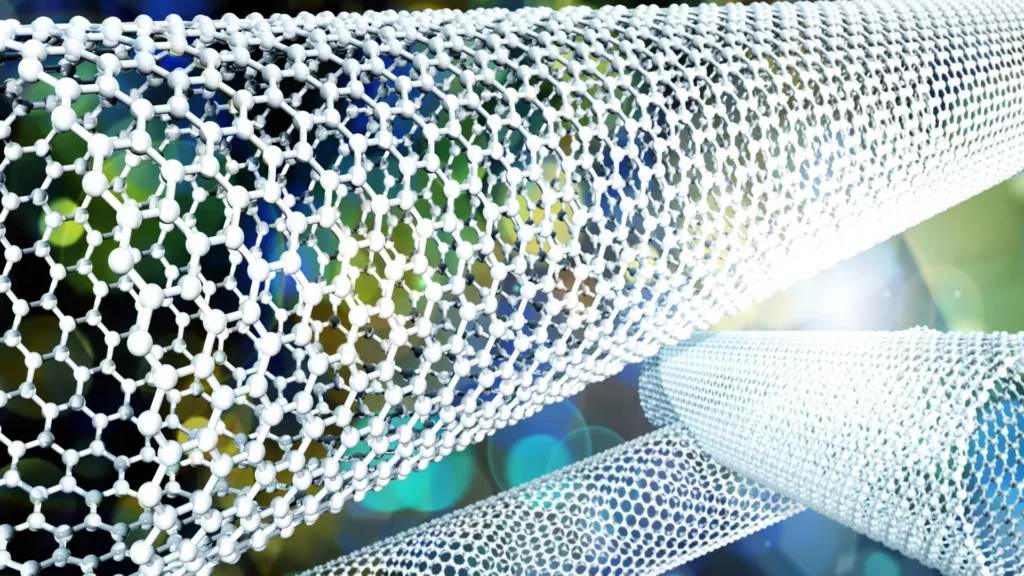

Composite materials, made of matrix and reinforcement, have evolved to the point of becoming indispensable in demanding industries.

Cavitation is a phenomenon that affects the performance of hydraulic systems, characterized by the formation and collapse of vapor bubbles.

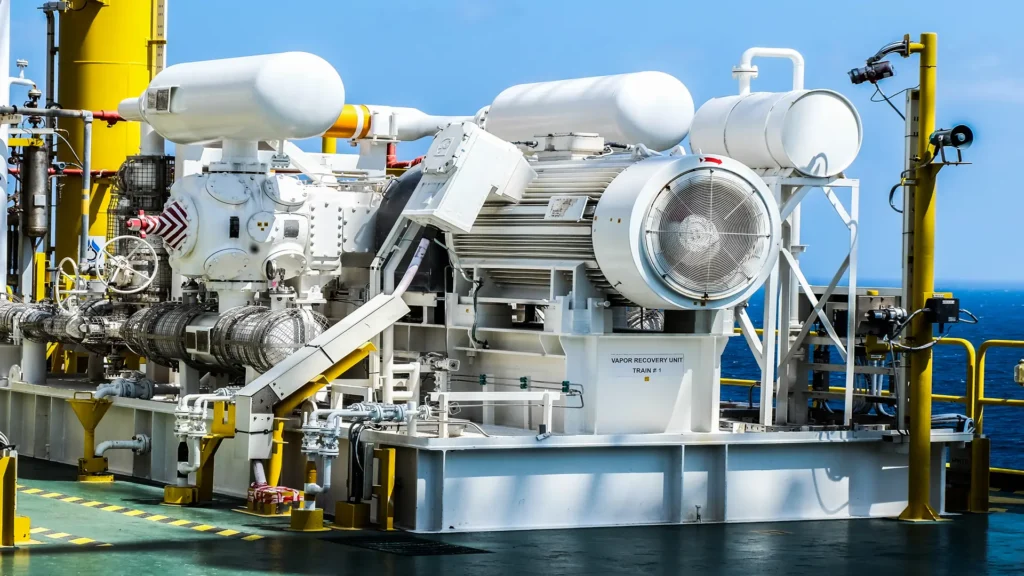

Surge in centrifugal compressors, its causes, symptoms and how it affects performance and mechanical integrity.

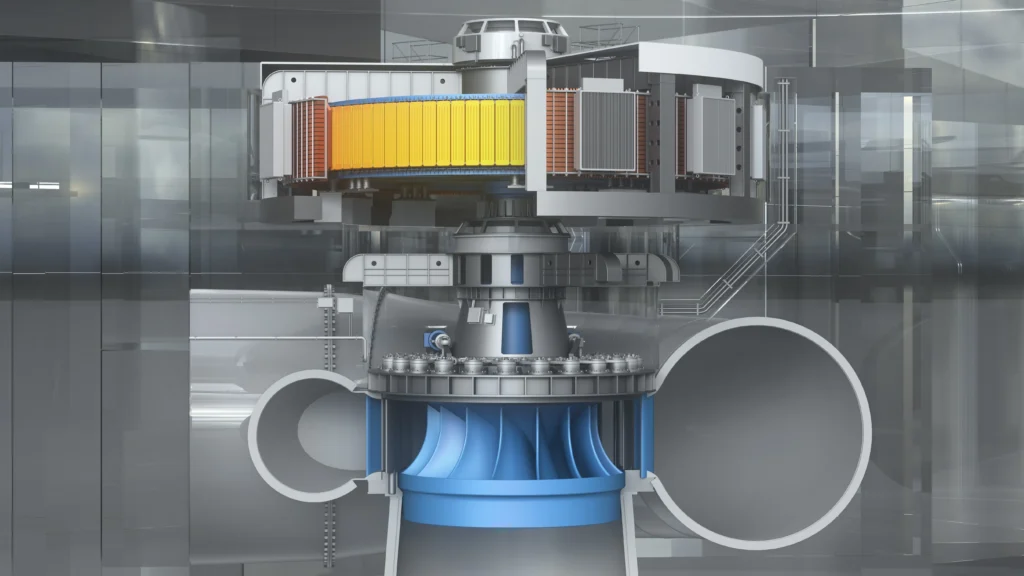

Hydraulic turbines convert water's kinetic energy into mechanical energy, driving hydroelectric efficiency.

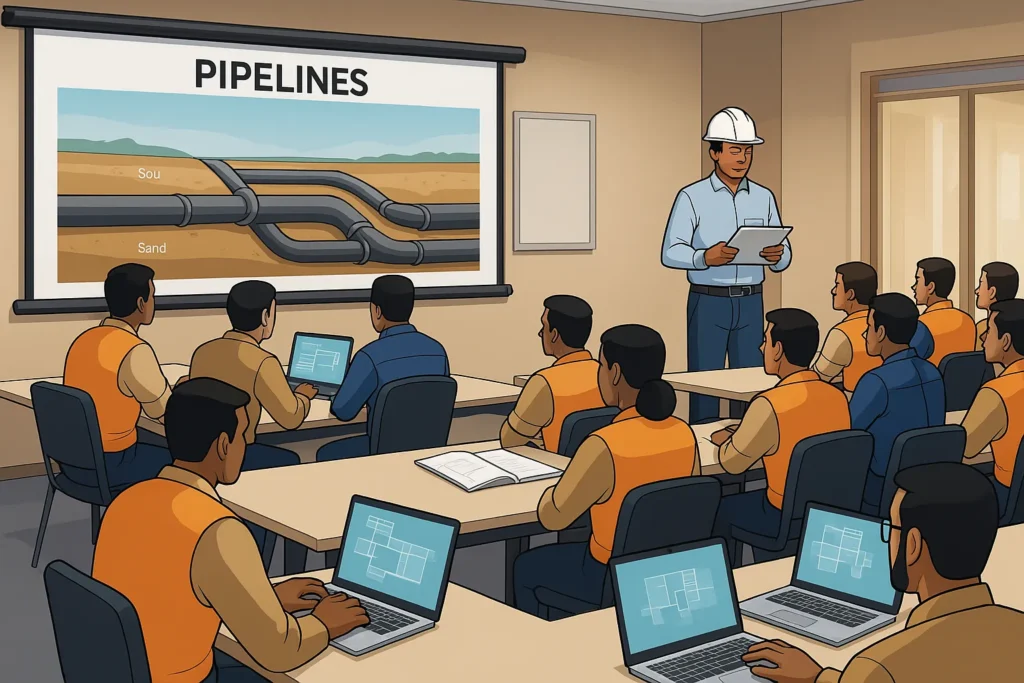

Adequate training of operators in pipeline safety is essential to mitigate risks and ensure operational continuity.

Salinity meters play a key role in the management and conservation of water resources.