Advanced analytics redefines global industrial processes

Advanced Analytics processes large volumes of data using statistics, machine learning and artificial intelligence, providing key insights for the industry.

He has more than 40 years in the oil and gas industry and is an expert in Level I Ultrasonic maintenance and inspection. His commitment to excellence ensures the reliability of critical equipment. He stands out for his vast experience, comprehensive understanding of methodologies and adaptability to new technologies.

Advanced Analytics processes large volumes of data using statistics, machine learning and artificial intelligence, providing key insights for the industry.

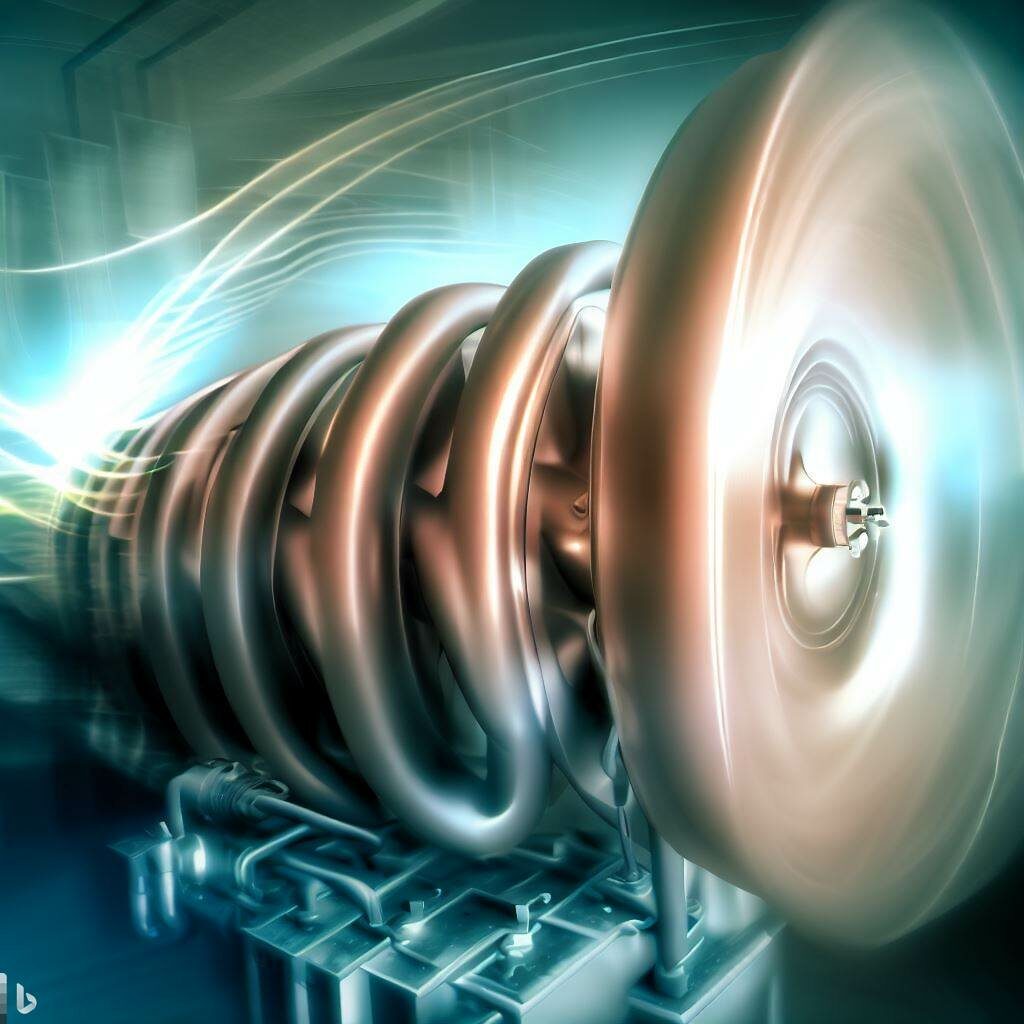

Vibration analysis in gas turbines is used to determine the operating and mechanical conditions of the equipment. A big advantage is that vibration analysis can identify developing problems before they become too serious and cause unscheduled downtime.

The circular economy redefines how the energy sector manages waste and leverages resources, aiming for greater operational efficiency.

Intelligent maintenance systems can be used to improve existing predictive, preventive and corrective maintenance programs, which provide functional, optimal and efficient support, allowing the implementation of intelligent maintenance systems.

The energy transition and the labor market is not a new aspect in this sector, as the world moves towards a circular economy and greater sustainability, this market is expanding to include new roles and specialized skills.

Each type of renewable gas is associated with a color that defines its origin, composition and function within the decentralized, low-carbon energy matrix.

The mining industry is adopting renewable energy sources such as wind and solar to strengthen competitiveness and reduce dependence on fossil fuels.

Pipeline inspection practices in light product terminals, focusing on integrity verification, operations safety, and maintenance strategies.

Learn how vibration analysis and the severity chart allow the diagnosis of mechanical failures in rotating machinery and the-optim interiores of industrial predictive maintenance.

Among the most challenging aspects of the job of a machinery professional or vibration analyst; is to decide whether a running machine should be taken out of service due to a detected problem or allowed to continue operating.