The critical role of blowers in the cleaning of industrial boilers

Improving efficiency by using blowers in boiler cleaning industrial.

He has more than 40 years in the oil and gas industry and is an expert in Level I Ultrasonic maintenance and inspection. His commitment to excellence ensures the reliability of critical equipment. He stands out for his vast experience, comprehensive understanding of methodologies and adaptability to new technologies.

Improving efficiency by using blowers in boiler cleaning industrial.

Addressing the applications of turbogenerators in efficient electricity production.

Boost efficiency in the industry through Enterprise Asset Management (EAM).

Implement remote monitoring technologies for unconventional gas wells.

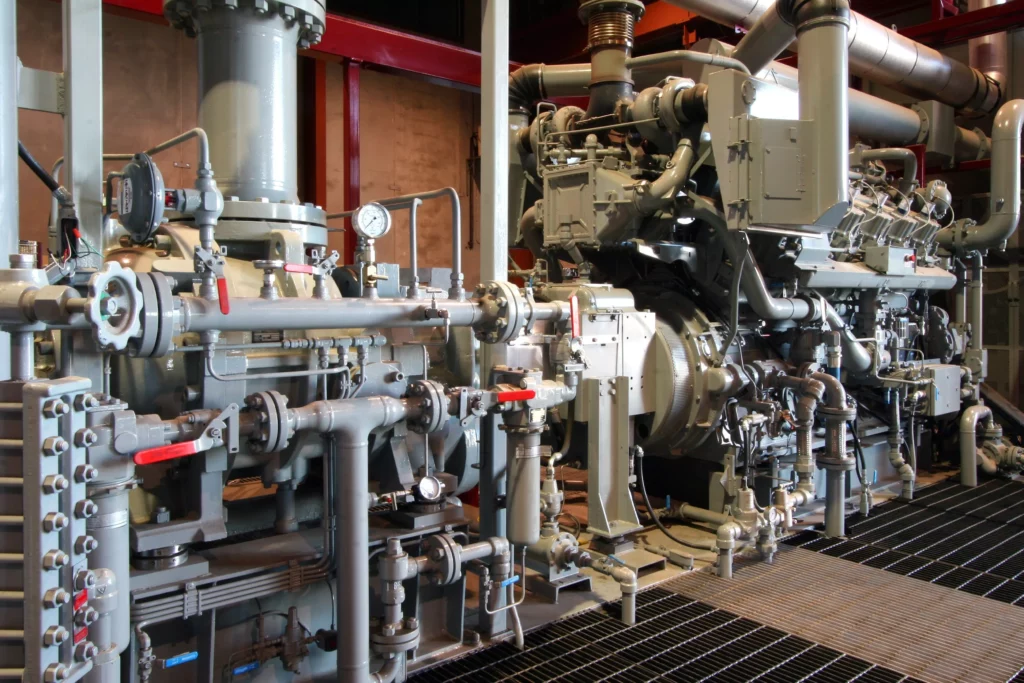

Introduction Natural gas compression offers significant benefits for the economy and energy sustainability. Natural gas compression systems facilitate the transportation of gas over long distances through pipelines, enabling…

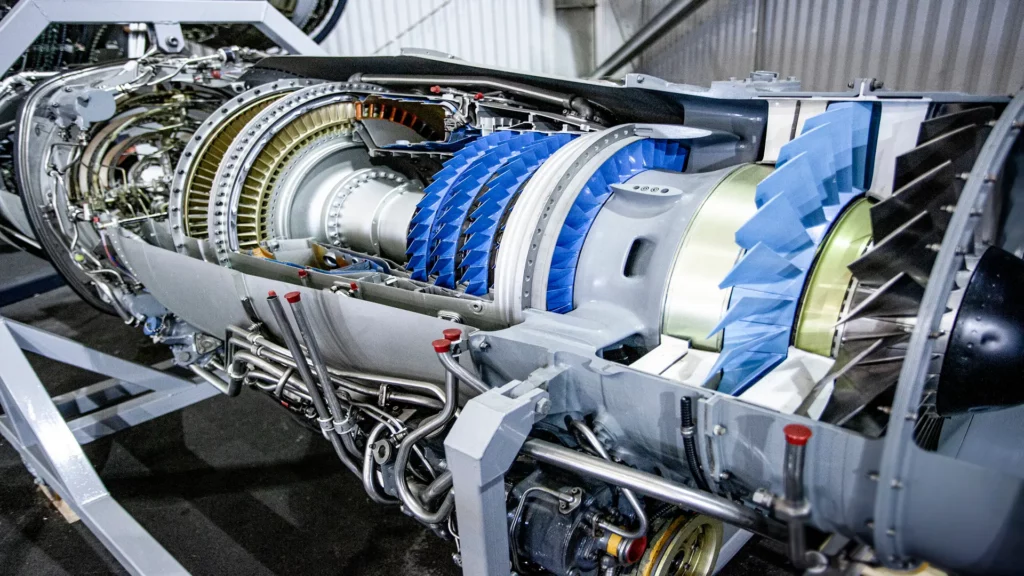

Discover how the Brayton cycle drives gas turbines, optimizing their performance and efficiency.

This comprehensive guide covers API 610, 674, 676, 682, and 685 standards, helping you make informed decisions for critical process applications.

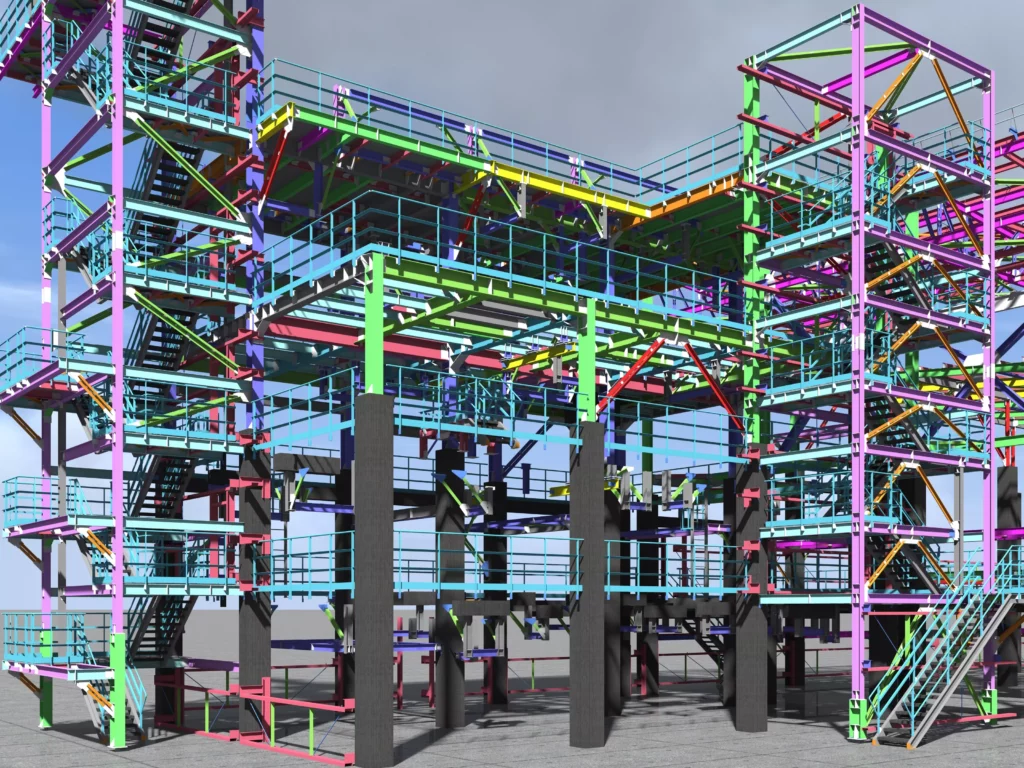

BIM technology in sustainable construction centralizes project information, improving quality, reducing costs, and contributing to green design.

Author: Analyst. Jose Lopez, March 15, 2024. Pressure Relief Valves (PRV) are safety components in industrial plants, protecting systems against overpressure situations that could cause damage or even catastrophic consequences. They are designed to release overpressurization in order to protect assets, following international standards and regulations.

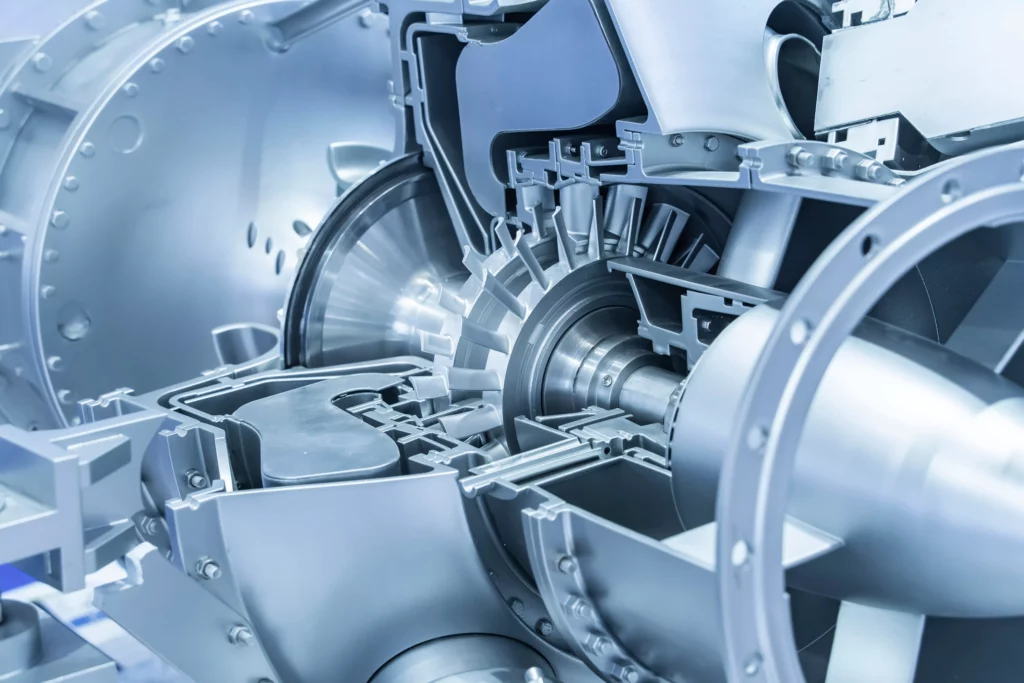

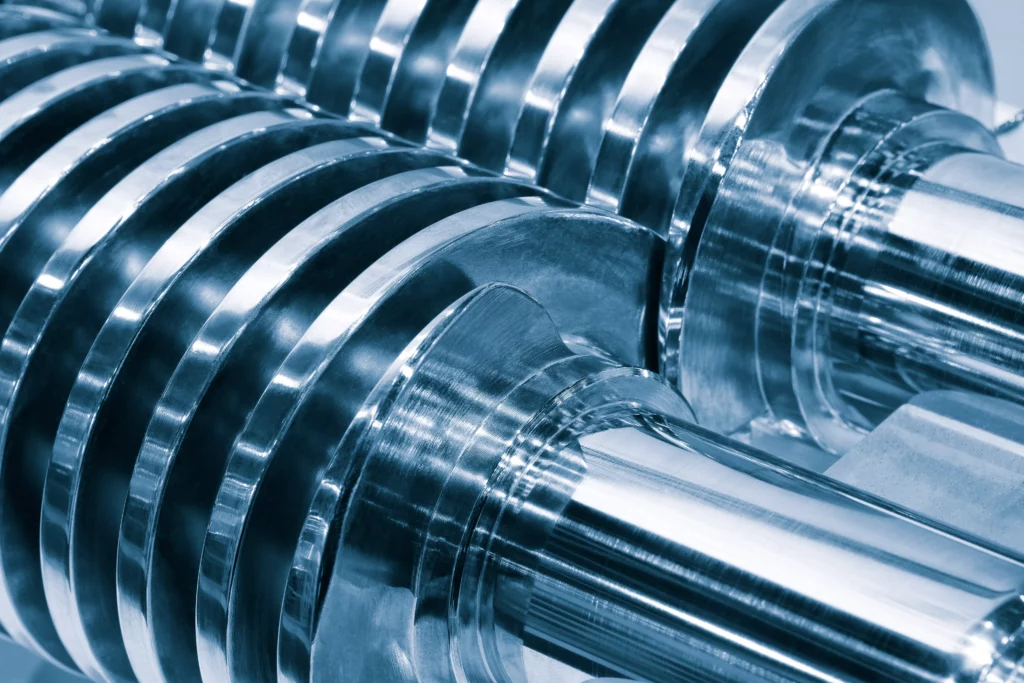

Author: Inspector. José López, 08 March 2024. Maximizing efficiency in rotating equipment is a fundamental element in various industries. Efficient rotating equipment leads to cost savings, extended equipment life, improved safety, increased productivity and better resource management.

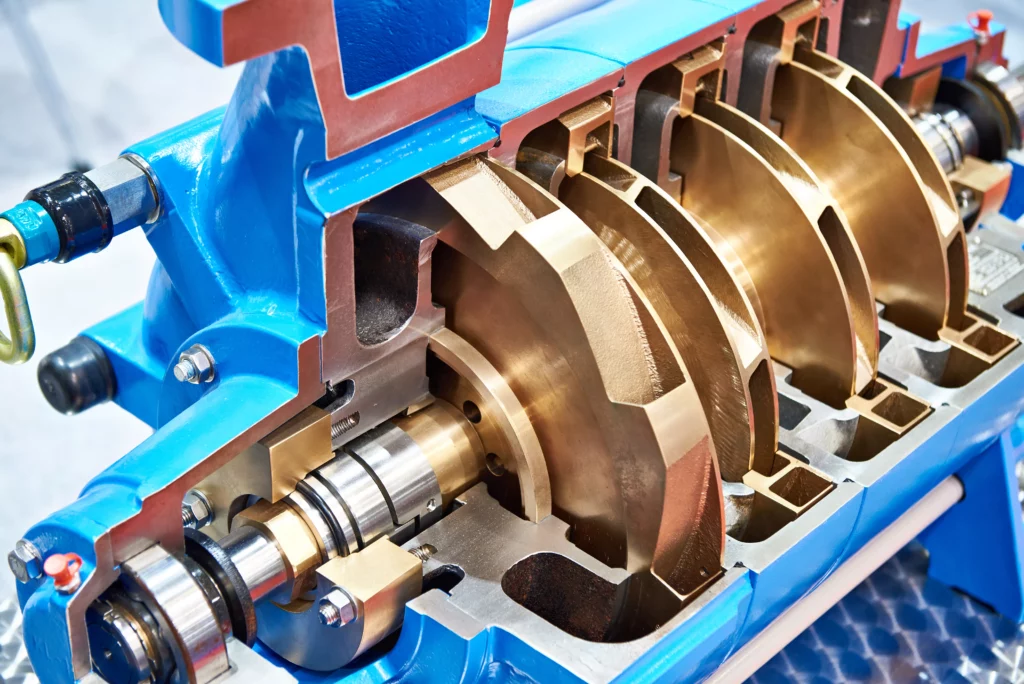

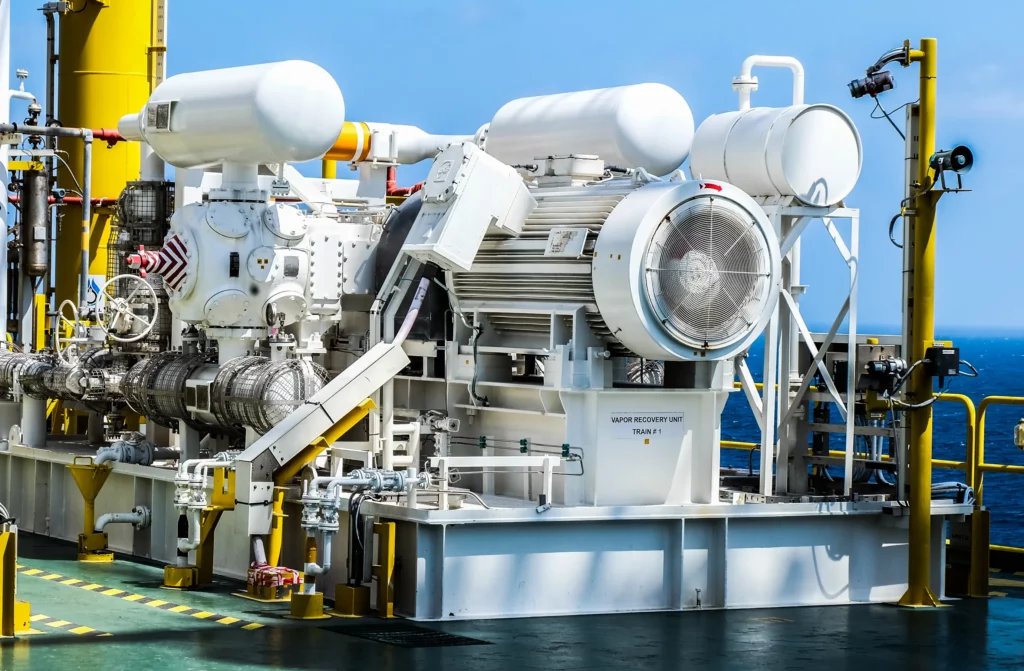

Author: Analyst. José López, 01 March 2024. A compressor is a device capable of increasing the pressure of a compressible fluid while reducing its volume. They are important components in the petroleum industry, playing a key role in the production, processing and transportation of natural gas through a variety of equipment, including pipelines, valves, separators and filters, by providing the necessary pressure and flow. Driving efficiency and profitability throughout the hydrocarbon supply chain.

Author: Analyst. José López, February 15, 2024. Compressors in gas flaring play a very important role in a variety of industrial applications involving the handling and transfer of gases. However, its effectiveness is only achieved when the technology is properly selected and applied in the relevant contexts.