Coke drums: Inspection, evaluation and repair

Inspection, evaluation and repair methods for coke drums in delayed coker units.

Mechanical Engineer with specialization in industrial maintenance. 43 years of experience in the oil, petrochemical, gas, metalworking and food industries. Content developer, expert analyst in equipment and corrosion inspection and plant shutdown technical management. Qualified and certified in non-destructive testing techniques UT, PT, VT, MT, RT.

Inspection, evaluation and repair methods for coke drums in delayed coker units.

Control room operators supervise industrial processes, making critical decisions that affect plant efficiency, safety and productivity.

Key analysis and recommendations for managing landslide risks in pipelines according to API RP 1187.

Analyzing the key differences between brazing and soldering in industrial processes.

Improving maintenance planning through effective implementation of RCM in the industry.

Analyzing best practices to improve the durability of marine hoses in offshore operations.

OCIMF guidelines ensure safety and efficiency in managing friction chains for SPM systems.

Risk prevention through equipment maintenance ensures safety and efficiency.

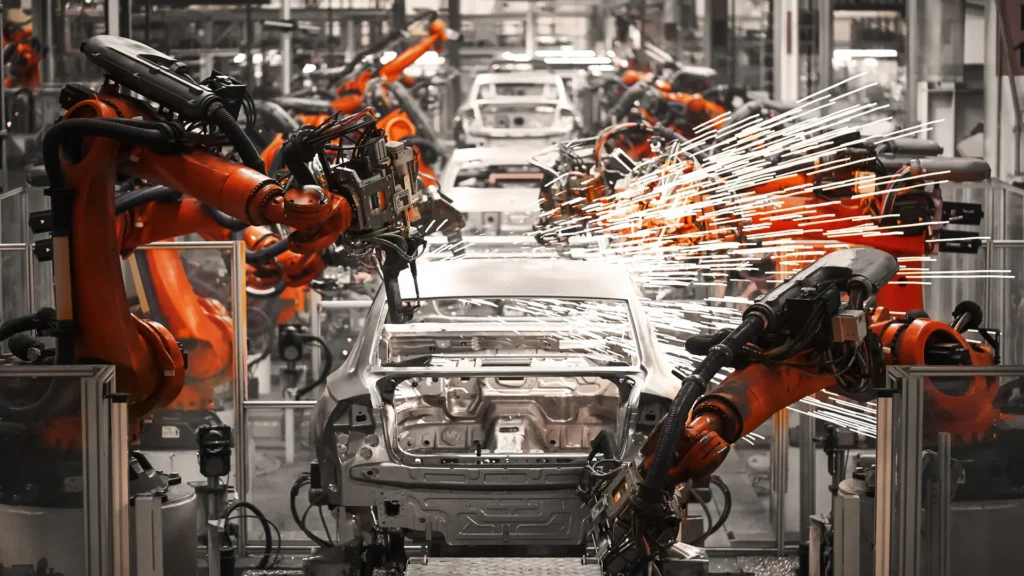

Internal welding defects, their causes, effects, and how to prevent them effectively.

Increasing asset life by implementing condition-based maintenance and real-time data monitoring.

Understanding the advantages and applications of square groove welding in metal joining.

Understanding how MIG welding revolutionizes manufacturing processes with high efficiency, versatility, and automation.