Explosion welding applied to cladding of dissimilar metals

Reliable and efficient technology for joining dissimilar metals using explosion welding in industrial cladding.

Mechanical Engineer with specialization in industrial maintenance. 43 years of experience in the oil, petrochemical, gas, metalworking and food industries. Content developer, expert analyst in equipment and corrosion inspection and plant shutdown technical management. Qualified and certified in non-destructive testing techniques UT, PT, VT, MT, RT.

Reliable and efficient technology for joining dissimilar metals using explosion welding in industrial cladding.

Subsea pipeline protection is essential for the safe and continuous operation of offshore power grids, ensuring the integrity of these critical systems.

Analysis of premature corrosion failures and their impact on the reliability of industrial assets.

Bunkering demands operational control, traceability, and MARPOL Annex IV compliance to ensure safety and environmental sustainability.

Data analysis strengthens Non-Destructive Testing (NDT), to manage defects with greater accuracy and anticipation.

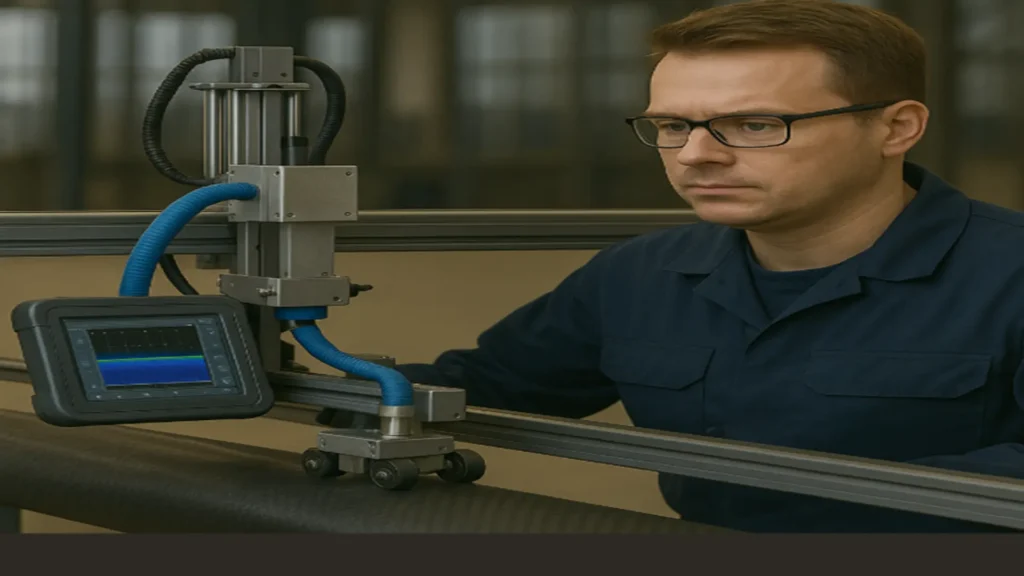

Innovation in CFRP NDT with Ultrasonic Testing by Adaptive Segmentation

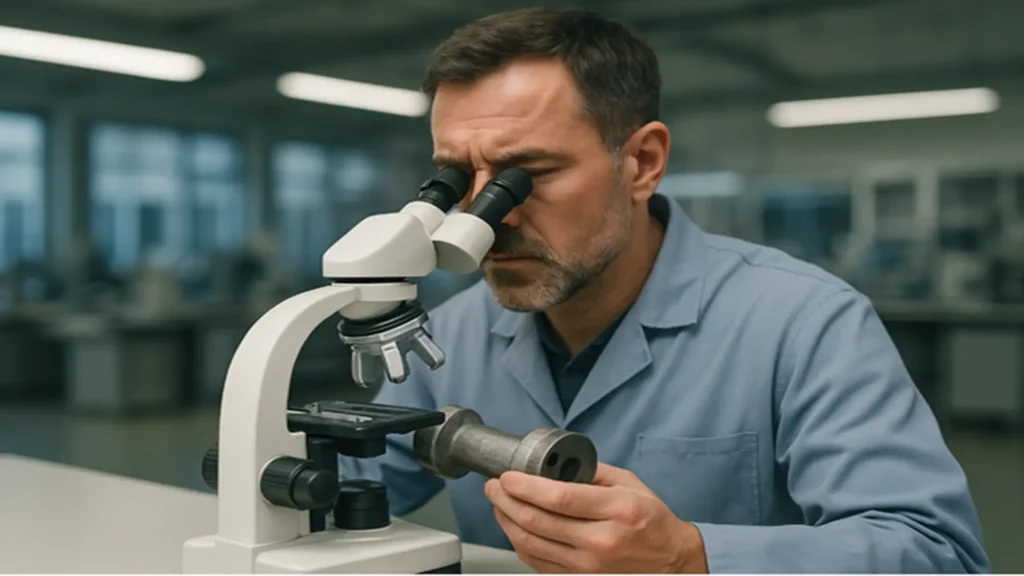

Positive material identification avoids critical errors by validating specifications in the field, improving quality control and operational efficiency.

Anodized aluminum improves durability, corrosion resistance and aesthetics, being essential in several industries.

Technical analysis of the rotary kiln: operation, models, industrial uses, and innovations in thermal design.

Techniques, innovations, and challenges in nuclear welding for power plants: a focus on safety and quality.

Advanced CFRP solutions for tank rehabilitation without welding or long shutdowns.

Stainless steel is essential in various industries for its corrosion resistance, durability, versatility and relevant applications.