Non-Destructive Testing (NDT) comprises methods designed to assess the condition of materials, components, and equipment without affecting their serviceability. Its function is to identify discontinuities, degradation, and early damage mechanisms to determine service fitness and remaining life.

In the energy sector, NDT is a cornerstone of integrity management, supporting maintenance decisions, reducing unplanned failures, and optimizing availability. The evolution toward advanced techniques, digitalization, and remote inspection drives its growth in the U.S., Europe, and LATAM.

Main topics

This section gathers technical content aimed at professionals requiring a precise and applied view of NDT technologies.

Key topics include:

- Volumetric testing (UT, PAUT, TOFD)

- Surface techniques (MT, PT, VT)

- Digital and computed radiography

- Remote inspection and robotics

- Defect evaluation and remaining life assessment

- ASNT, ISO, API, and SNT-TC-1A standards

- Applications in O&G, petrochemical, energy, and mining

NDT is essential to ensure structural integrity and operational continuity of critical assets. Technical challenges include qualifications of techniques, accurate interpretation of indications, inspection in complex geometries, and adoption of advanced technologies.

Non-destructive testing: Advances, methods and industrial applications

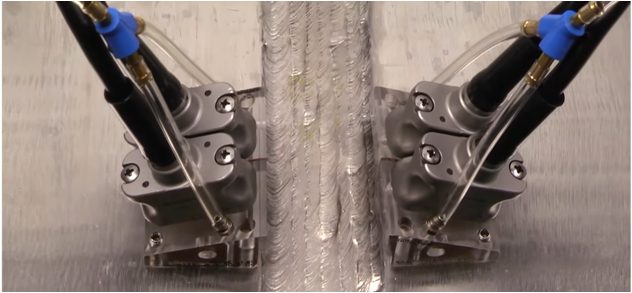

The Krautkrämer made history at the inspection

Unlock Material Secrets with XRF: Positive Material Analysis

Evaluation of welds in austenitic stainless steel

Importance of visual inspection for the oil & gas industry

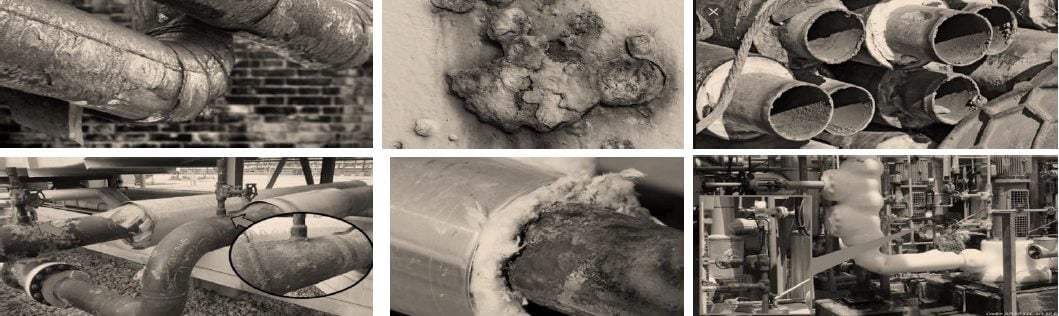

Detecting Corrosion Under Insulation with Advanced NDT Methods

Revolutionize Safety: Non-Destructive Testing for Industry Systems

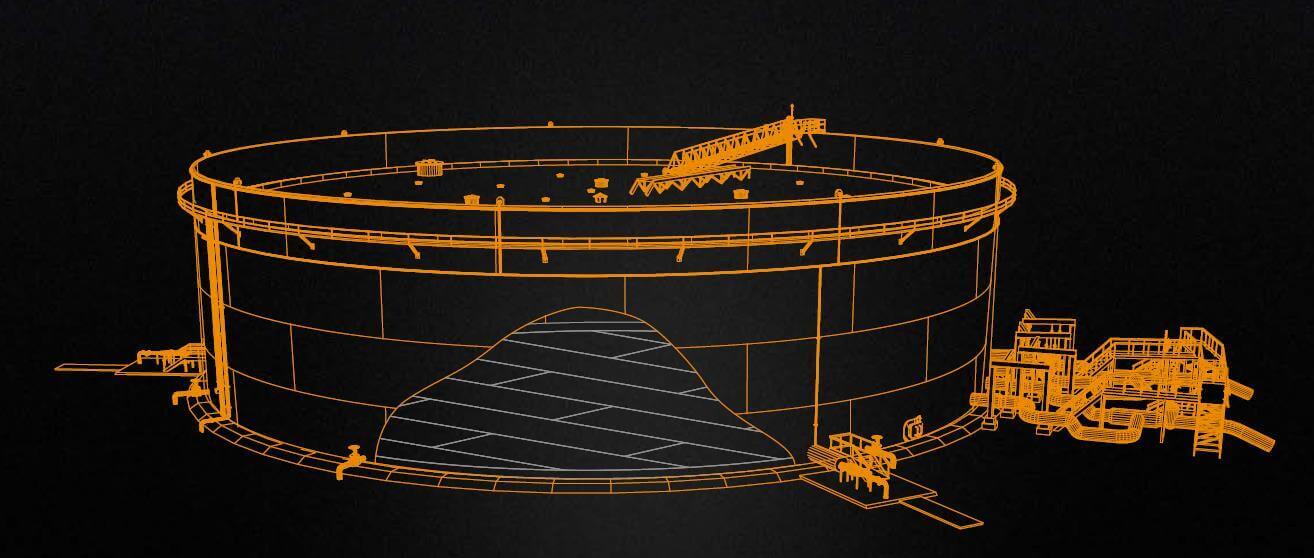

Unlocking Tank Commissioning: The Crucial Role of NDT