Mechanical Integrity addresses the life cycle management and inspection of critical equipment to ensure the safe and reliable operation of energy and industrial infrastructure. The focus is on mitigating catastrophic failure risks through corrosion control, reliability monitoring, and the application of international codes and standards.

This field is vital for maintaining operational continuity and protecting lives. We analyze asset management strategies and non-destructive testing (NDT) techniques applied in the US, Latin America, and Europe. Specialized knowledge in mechanical integrity turns risk into predictability.

MAIN TOPICS

- Assets

- Codes and Standards

- Reliability

- Corrosion and Materials

- Engineering

- Equipment Inspection

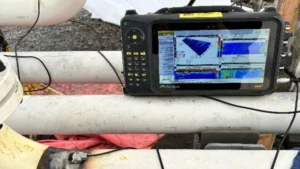

- Non-Destructive Testing (NDT)

- Applied Case Studies

Mechanical integrity is the determining factor between operational continuity and an unexpected shutdown. Inspenet dedicates this space to providing technical knowledge that extends the useful life of assets and minimizes risk. Professionals will find technical articles and applicable knowledge on equipment inspection and reliability.

API 510: Best practices for inspecting vessels in service

Floating roof seals: functions, types, and materials

Storage tanks: Common faults, causes, and solutions

Barriers and successes in integrating maintenance methodologies

Physical asset management in maintenance

Decouplers: The Solution for AC Interference on Cathodically Protected Pipelines

Condition-based monitoring of critical assets

Corrosion in industrial cooling systems: mechanisms and control