Across global industries, from energy and transportation to aerospace, marine, and civil infrastructure, the demand for advanced protective materials has reached an unprecedented level. Traditional coatings have long served as passive barriers, delaying deterioration but lacking the ability to detect, respond to, or adapt to environmental changes. As a result, hidden corrosion, microcracking, moisture ingress, and mechanical fatigue often remain undetected until failure is already underway, leading to costly repairs, safety risks, and operational downtime.

To address these challenges, Eninco Engineering B.V. has developed a breakthrough solution: intelligent multifunctional coatings powered by nanosensor-integrated microcapsule systems. This next-generation technology transforms coatings from passive protection into active, self-monitoring, self-healing, and adaptive materials capable of safeguarding critical assets in real time.

The technology: How nanosensors and microcapsules work together

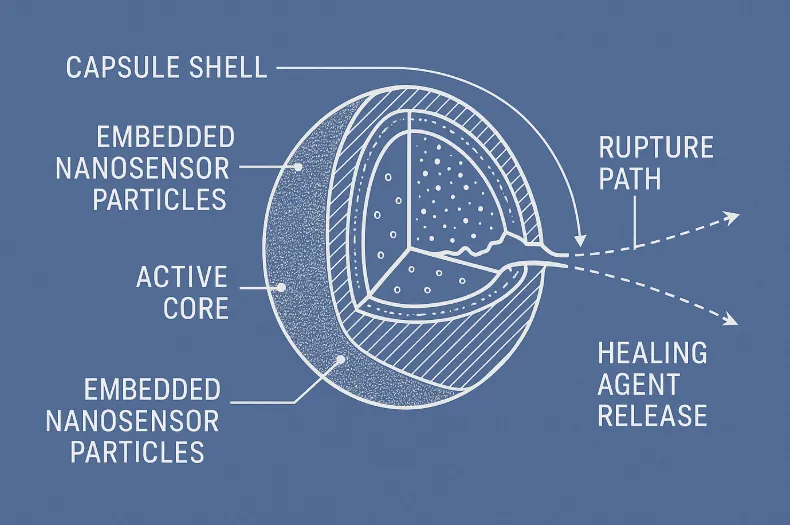

At the core of this innovation lies a hybrid architecture combining trigger-sensitive nanosensors with functionalized microcapsules embedded throughout the coating matrix. Each microcapsule acts as a protective reservoir containing active agents such as corrosion inhibitors, pH stabilizers, crack-healing monomers, or anti-fouling compounds. Meanwhile, the nanosensors continuously monitor environmental and structural conditions.

When the coating experiences changes such as pH shift, chloride penetration, microcrack formation, temperature shock, or moisture ingress the nanosensors detect the abnormal signal and activate the surrounding microcapsules. This controlled release mechanism ensures that the coating responds only when and where necessary, dramatically enhancing efficiency and minimizing chemical consumption.

*(Based on reference [1]) Source: Eninco.

The system functions through four primary mechanisms:

- Detection: Nanosensors identify early-stage deterioration signals that are invisible to the human eye and undetectable by conventional coatings.

- Triggering: Once activated, nanosensors communicate the precise location and severity of the change.

- Release: Microcapsules open selectively and deliver the functional agents required to neutralize corrosion, repair microcracks, or repel biofouling organisms.

- Regeneration: The coating stabilizes, heals, or restores itself, extending the material’s operational lifespan.

This integrated approach provides intelligent, localized protection a significant advancement over coatings that release inhibitors continuously or uniformly without regard to actual environmental conditions.

Benefits and advantages for industry

Early detection and predictive maintenance

One of the most valuable capabilities of this technology is its ability to detect corrosion precursors before they evolve into structural damage. By identifying changes in pH, ion concentration, or microcrack propagation, the system enables maintenance teams to act proactively. This reduces unplanned shutdowns and extends the lifespan of assets.

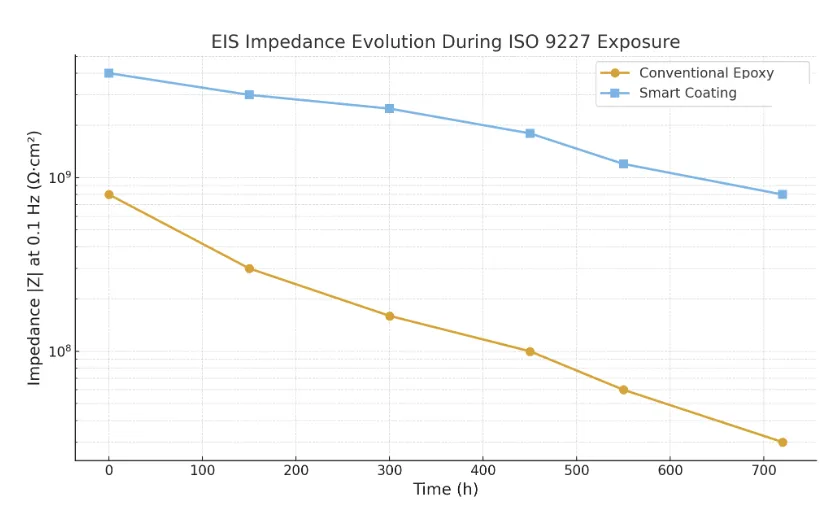

Figure 3 illustrates the comparative barrier performance of the Smart Coating vs. Conventional Epoxy during 720 hours of salt-spray exposure (ISO 9227). The smart coating maintains significantly higher impedance (|Z|₀.₁Hz), confirming superior corrosion protection and reduced barrier degradation.

Self-healing and adaptive behavior

Microcapsules supply the exact type and amount of agent needed for the specific defect encountered. For example:

- A microcrack triggers capsules containing polymeric healing agents.

- Chloride attack triggers the release of corrosion inhibitors.

- pH changes activate alkaline stabilizers.

This adaptive response is key to preventing local damage from spreading.

Reduced environmental impact

Unlike coatings that rely on continuous biocide release or large volumes of inhibitors, the intelligent system releases active agents only when required. This significantly reduces chemical pollution and supports stricter environmental regulations especially in marine and freshwater ecosystems.

Enhanced structural reliability and safety

For bridges, pipelines, aircraft components, offshore structures, and military assets, undetected degradation poses severe risks. Intelligent coatings function as a first line of defense, providing early warnings and localized intervention, thereby increasing the safety margin and reducing long-term operational risks.

Cost efficiency and long-term savings

While advanced smart coatings represent a technological leap, their long-term financial benefits are substantial:

- Reduced maintenance frequency

- Fewer emergency shutdowns

- Extended service life of coated structures

- Lower labor and inspection costs

- Fewer replacements of corroded or damaged components

Industries with high corrosion exposure (oil & gas, marine transport, renewable energy, chemical processing, and civil engineering) stand to benefit the most.

Key application sectors

Energy and petrochemical infrastructure

Pipelines, storage tanks, refineries, and offshore platforms are continuously exposed to corrosive agents. Intelligent nano-sensor coatings detect early-stage corrosion and prevent failure, reducing both environmental risk and operational downtime.

Aerospace and defense

Aircraft fuselages, wings, landing gear components, and defense equipment endure extreme temperature fluctuations, mechanical stress, and humidity cycles. The ability to self-heal microcracks and adapt to environmental changes greatly enhances durability and safety.

Marine and offshore structures

Biofouling and corrosion severely affect ships, hulls, ports, and offshore wind farms. The nanosensor-triggered anti-fouling microcapsules offer a non-biocidal alternative, protecting ecosystems while maintaining operational performance.

Civil infrastructure

Bridges, tunnels, rail systems, and coastal structures face combined corrosion and mechanical stresses. Intelligent coatings delay structural degradation and provide crucial data for asset-management systems.

Renewable energy and hydrogen systems

Hydrogen embrittlement, moisture ingress, and pH changes are major threats in next-generation energy systems. Responsive coatings help stabilize these environments and ensure safer operation.

Current development status and outlook

The technology currently stands at Technology Readiness Level (TRL) 6, meaning it has successfully passed laboratory validation and pilot-scale testing under simulated environmental conditions. The next step includes industrial implementation, field trials, and scaling to TRL 7 through partnerships with energy, aerospace, and infrastructure operators.

Eninco Engineering B.V. is establishing collaborations in Europe, the United States, and the Middle East to integrate these intelligent coatings into real-world applications, supported by:

- Performance validation programs

- Predictive monitoring platforms

- Industrial pilot production

- Regulatory compliance and certification pathways

The long-term vision includes the integration of IoT-linked nanosensors and advanced data-analytics tools, enabling continuous structural-health monitoring directly from the coating layer itself.

Table : Performance summary of the innovative coating system. [2]

| Parameter | Value | Standard/Condition |

| Total dry film thickness (DFT) | 172 ± 9 μm | ISO 2808 |

| Adhesion strength | 6.2 ± 0.4 MPa | ISO 4624 |

| NSS corrosion resistance | < 1.5 mm creep (720 h) | ISO 9227 |

| Impedance (|Z|₀.₁Hz) | 1.4 × 10⁷ Ω·cm² | ICE |

| NO₂ detection limit (LOD) | 0.04 ppm | ZnO sensor response |

| VOC sensitivity | Detectable (toluene/ethanol) | Cross-selectivity tested |

| Humidity drift | < 2.2% | Stability over cycles |

| AI classification accuracy | 95.6% | TinyML model |

| Wireless communication range | > 300 m | LoRaWAN (868 MHz) |

| Power supply | Solar microfilm | Energy harvesting |

A summary of the coating performance and embedded sensor functionality is presented in Tab. 1.

A new era of protective coatings

The introduction of nanosensor-integrated microcapsule coatings represents a major technological shift. For decades, protective coatings have served as static barriers. Today, they are evolving into dynamic, intelligent systems capable of sensing, reacting, and healing.

Industries facing severe corrosion and structural degradation can now adopt solutions that not only extend asset life but fundamentally transform maintenance strategies. With rising global concerns about safety, sustainability, and infrastructure resilience, intelligent coatings offer a path toward cleaner, safer, and more efficient industrial operations.

References

[1] Jitendra Chavhan, Manoj Prabhakar, Arulkumar Ganapathi, Michael Rohwerder b, Lakshman Neelakantan; Multifunctional Epoxy/PVDF smart coatings using ZIF-8 nanosensor for corrosion protection of mild steel: A study on synthesis and performance, Progress in Organic Coatings, Volume 203, June 2025, 109198.

[2] Arezoo Assarian, Innovative Coatings with Embedded Edge-Ai Sensors for Real-Time Environmental Monitoring in Urban Infrastructure, MTECH 2025 – 5th International Conference on Materials in Croatia

This article was developed by specialist Arezoo Assarian and published as part of the seventh edition of Inspenet Brief February 2026, dedicated to technical content in the energy and industrial sector.