Modal analysis with piezoelectric sensors for CBM maintenance

Operational modal analysis (OMA) has become a pivotal tool in the evolution of structural health monitoring, asset reliability, and predictive maintenance strategies.

Operational modal analysis (OMA) has become a pivotal tool in the evolution of structural health monitoring, asset reliability, and predictive maintenance strategies.

Technical analysis of advanced Risk-Based Inspection (RBI) technologies for atmospheric tanks, focused on safety, frequency, and prioritization.

Exploring how artificial intelligence and machine learning optimize operational risk assessment in oil and gas.

Implementing heat pump maintenance strategies that optimize performance and reduce energy consumption.

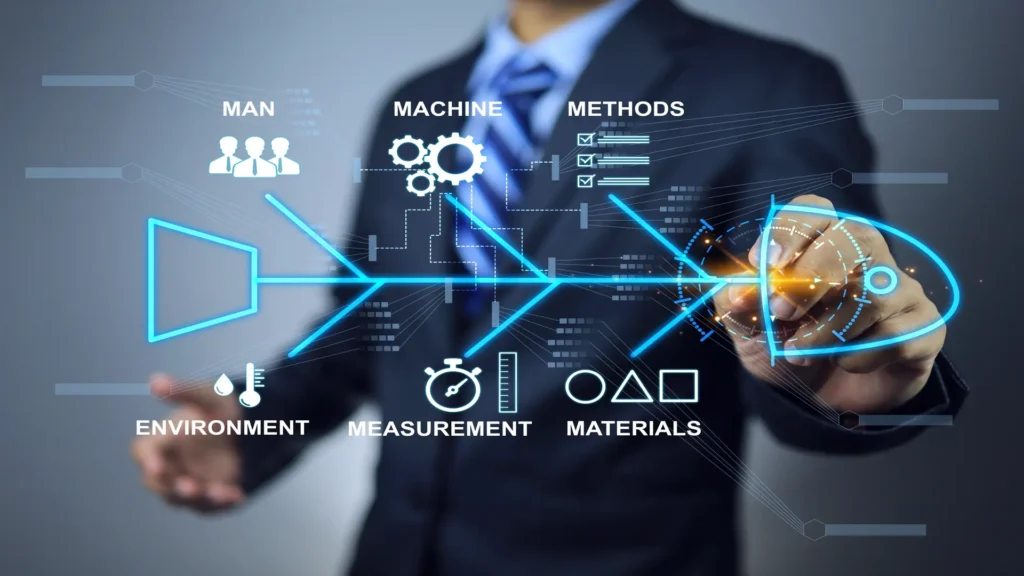

Highlighting how the cause and effect diagram drives continuous improvement and problem-solving in business processes.

Promote RCM strategies for floating roofs, ensuring efficiency, safety, and compliance in storage tank operations.

Highlighting the importance of reliability audits to maximize business ROI.

Highlighting the effectiveness of Root Cause Analysis (RCA) in industrial maintenance to identify problems quickly.

Reliability Centred Maintenance improves asset performance, reduces costs and operational risks.

Introducing the principles and benefits of Root Cause Analysis to improve equipment availability and reliability.

Optimizing maintenance management using performance indicators to improve effectiveness, efficiency and efficiency.

Electrical maintenance ensures regulatory compliance, guaranteeing safe and efficient operations, avoiding sanctions or penalties.