Certification and qualification in NDT: steps and regulations

Summary of the steps for qualifying and certifying NDT personnel under ISO 9712 and SNT-TC-1A.

Summary of the steps for qualifying and certifying NDT personnel under ISO 9712 and SNT-TC-1A.

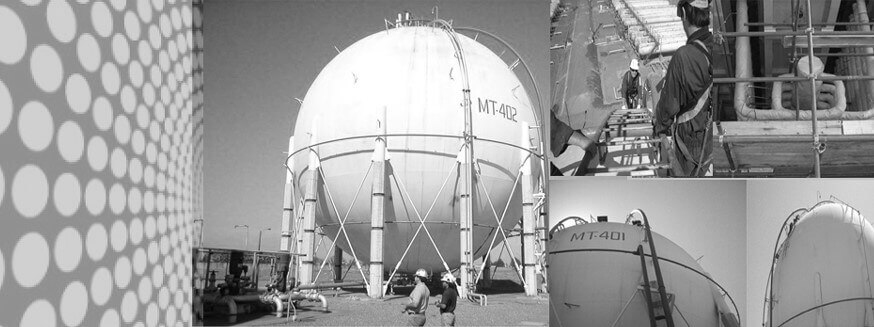

Inspection of storage tanks according to American Petroleum Institute (API) standards are important to prevent not only catastrophic failures, but also to avoid problems related to…

The field of storage tank inspections comprises in-service and out-of-service inspections of vertical and horizontal above-ground and subway tanks. A combination of techniques including engineering calculations…

Author: Ing. Carlos Álvarez, May 11, 2022. Visual inspection is a simple test compared to other non-destructive testing methods; however, since the main tool for carrying…

The company Waygate Technologies through its commercial representative the Testek Group, leaders in the manufacture and marketing of equipment and materials in non-destructive testing (NDT) solutions…

The Testek Group, in its expansion process to new markets in Latin America, announces that it is pleased to announce that they are the new official…

Storage tanks are equipment with infrequent maintenance periods, so they require continuous external inspections, to have a better control of their conditions during the time they…

This article presents current technologies, tools and procedures for diagnosing the condition and inspectability of natural gas pipeline systems.

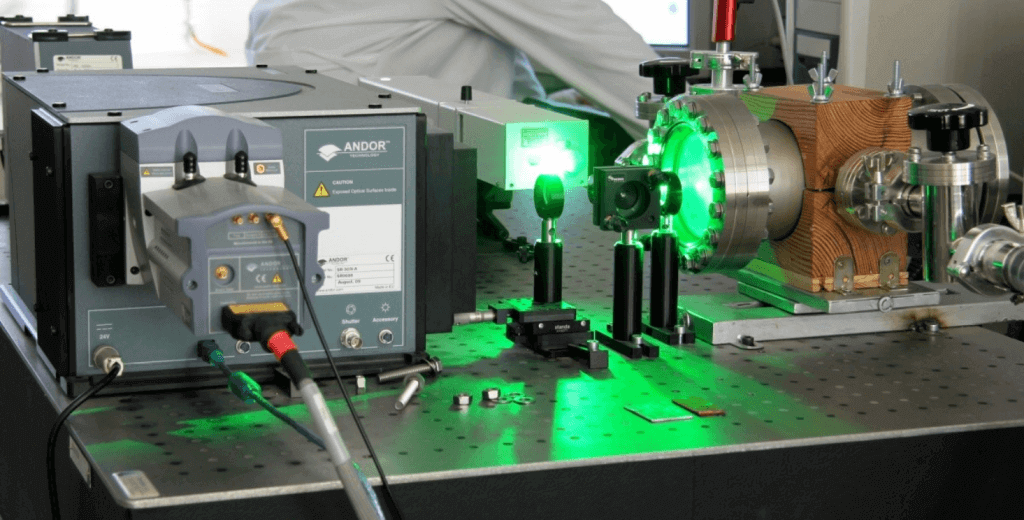

Summary Laser Induced Plasma Spectroscopy (LIBS) represents one of the most useful techniques for the selection and identification of materials. This article describes a brief summary,…

Summary. Brief dissertation about the characteristics of the Non-Destructive Testing (NDT) inspector and the peculiarities of our work as industrial inspectors; which is not only limited…

Acoustic Emission (EA) is a very versatile NDT method; during the evaluation, the structure is not required to be out of service. The application of this…

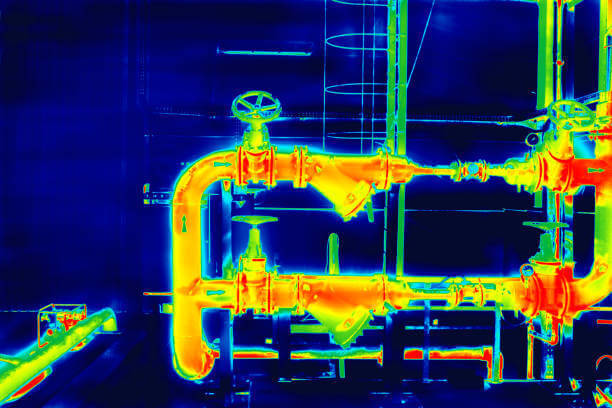

Thermography is one of the most common methods used by the Equipment Inspector in plants in service, to verify the existing conditions of any asset.