How the NDT industry benefits major productive sectors

How NDT industry improves integrity, safety and operational efficiency in different sectors.

How NDT industry improves integrity, safety and operational efficiency in different sectors.

Predictive maintenance reduces downtime and operating costs by anticipating failures through non-destructive analysis of equipment.

Application of NDT in the Foundry Industry: techniques, defects, properties, personnel selection and training.

Ensure quality and safety in the manufacture of pressure vessels.

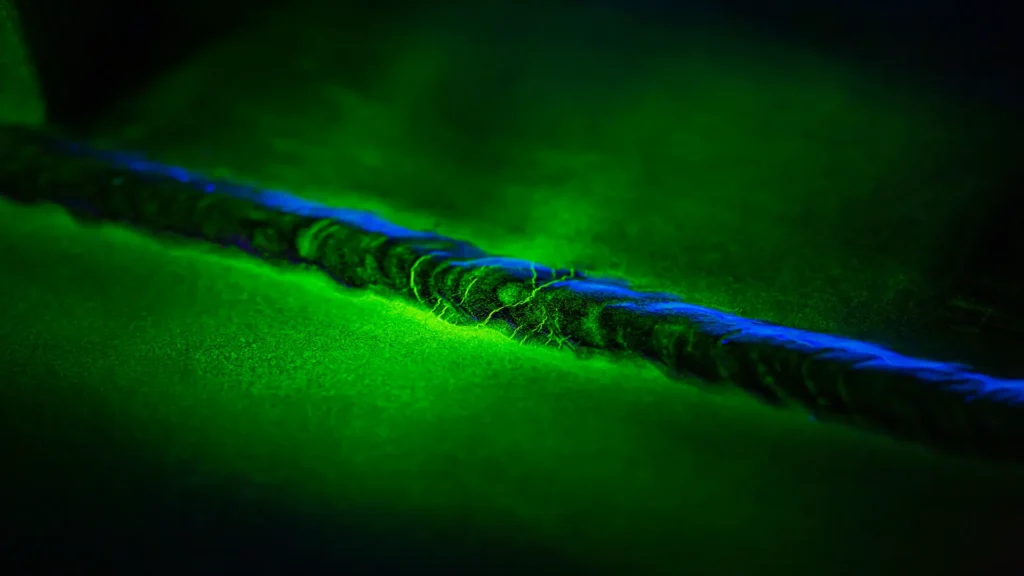

Detecting High Temperature Hydrogen Attack (HTHA) is most effective with wet fluorescent magnetic particles and magnetic flux.

The integration of automated NDT in Industry 4.0 enables real-time monitoring and improves predictive maintenance.

Emphasizing how the role of the ASNT in NDT standards contributes to industrial safety and quality.

Guarantee the quality of welds through the application of AWS Standards and Non-Destructive Testing.

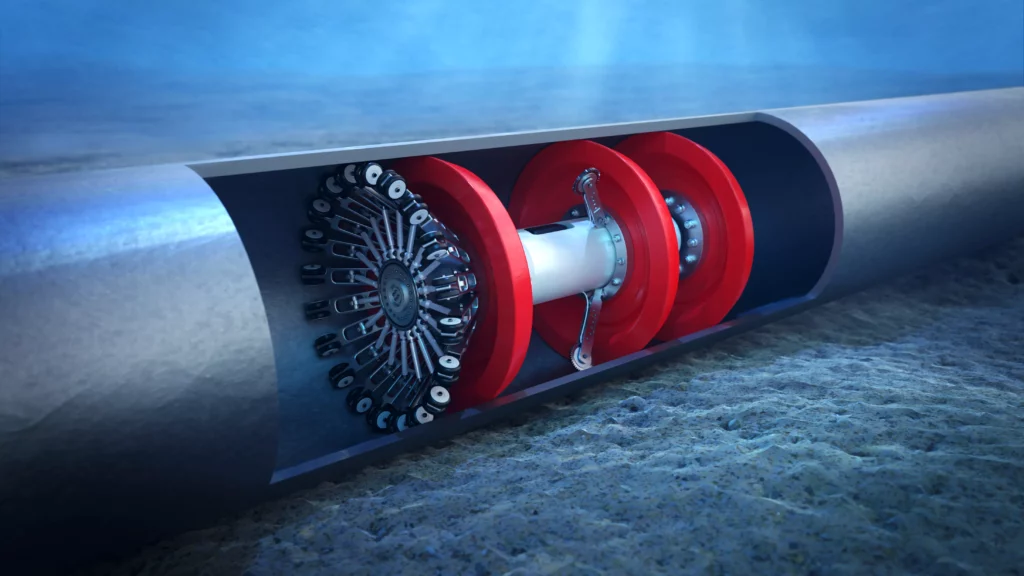

ILI allows for assessing the integrity of pipelines without halting their operation using a variety of technologies.

Under pipe support inspection is feasible with short-range guided waves and EMAT transducers.

The Pulsed Eddy Current Array technique is a useful tool in the inspection of structures and components at marine terminals.

ASTM E1211 standardizes and enhances leak detection with Acoustic Emission sensors, critical for industrial and environmental safety.