Portable methods for positive material identification

Positive material identification avoids critical errors by validating specifications in the field, improving quality control and operational efficiency.

Positive material identification avoids critical errors by validating specifications in the field, improving quality control and operational efficiency.

ASME B31.3 guides the design and operation of industrial piping, ensuring safety and reliability in critical systems within demanding environments.

Technical analysis of advanced Risk-Based Inspection (RBI) technologies for atmospheric tanks, focused on safety, frequency, and prioritization.

API 570, oriented to the inspection of in-service pipelines, and API 1169, focused on inspection during the construction of transportation pipelines, stand out for establishing technical…

Ensuring tank safety by complying with NFPA 30 in design and operation.

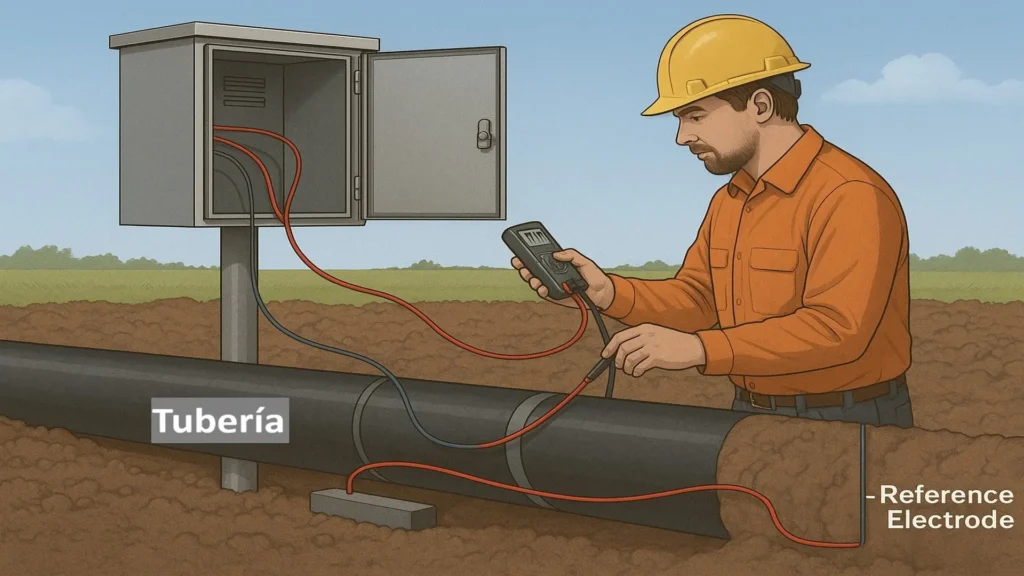

Orientation for professionals on the AMPP CP program, explaining its levels (CP1 to CP4), benefits and technical training in corrosion control.

Learn how to apply API 1169 in piping projects, improve safety, avoid failures and excel professionally.

Anodized aluminum improves durability, corrosion resistance and aesthetics, being essential in several industries.

Against the limits of traditional methods, advanced cathodic protection with VCI represents an efficient solution for aggressive subway environments in the petrochemical industry.

Clarifying the differences between corrosion vs. rust: know their differences, causes, and effects on the durability of metals.

Learn how NDT certifications can open doors to high-paying and in-demand careers worldwide, ensuring safety and innovation.

API Standard 650 in the petroleum industry: History, benefits and scope, with emphasis on the manufacturing processes, tests and acceptance tests that ensure the quality and…