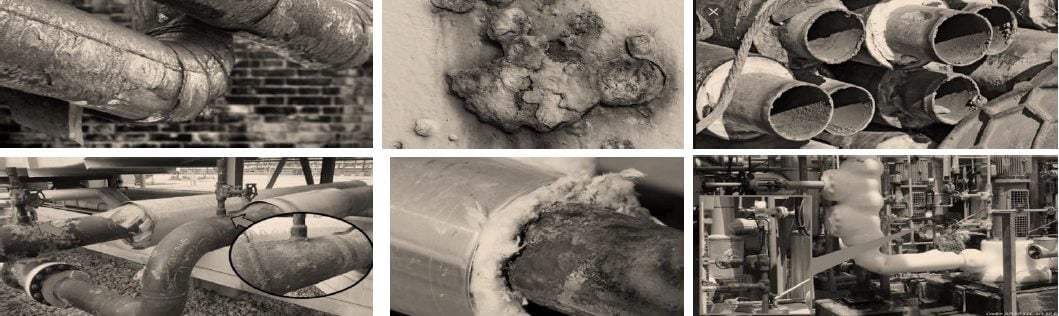

Detecting Corrosion Under Insulation with Advanced NDT Methods

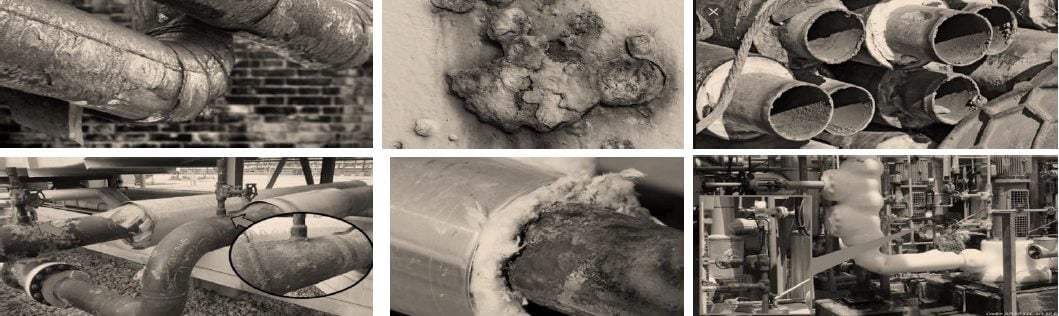

The selection of the NDT method depends on the type of insulation, wall thickness and accessibility of the pipe.

The selection of the NDT method depends on the type of insulation, wall thickness and accessibility of the pipe.

Non-Destructive Testing (NDT) is key to guaranteeing the quality of metallic materials used in industries: industrial pressure vessel plants, petrochemical plants, power or nuclear power plants,…

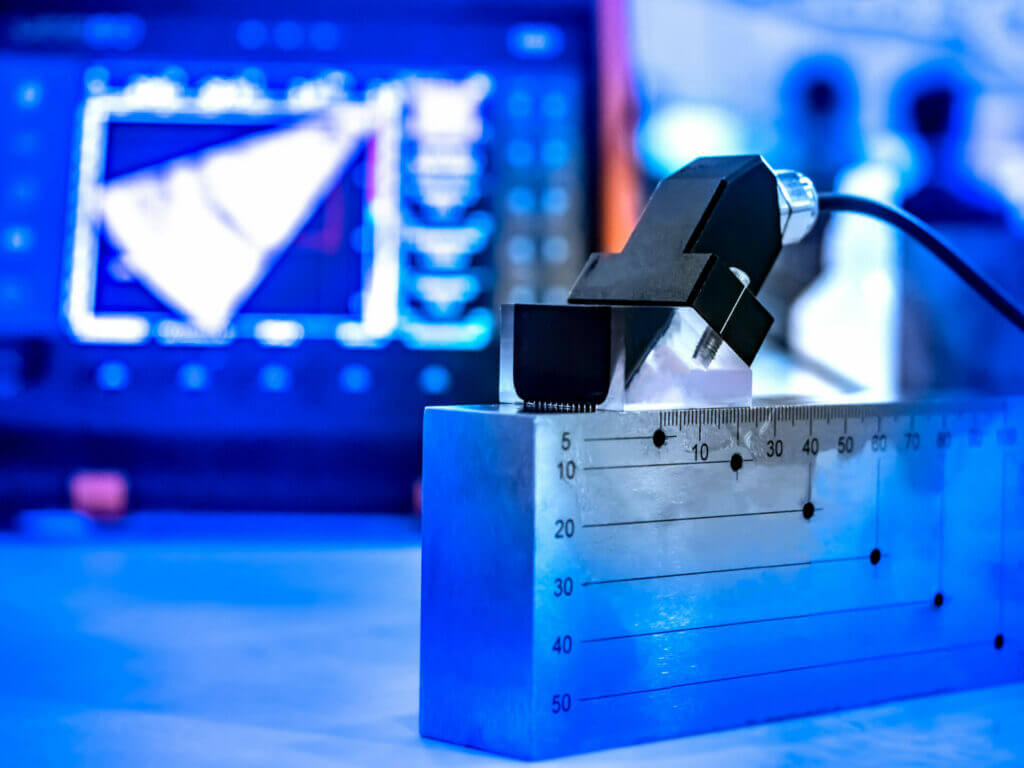

NDTs allow for the evaluation and assurance of optimal tank conditions during deployment, repair, and industrial maintenance.

NDTs ensure that a storage tank meets safe and operational conditions before being put into operation.

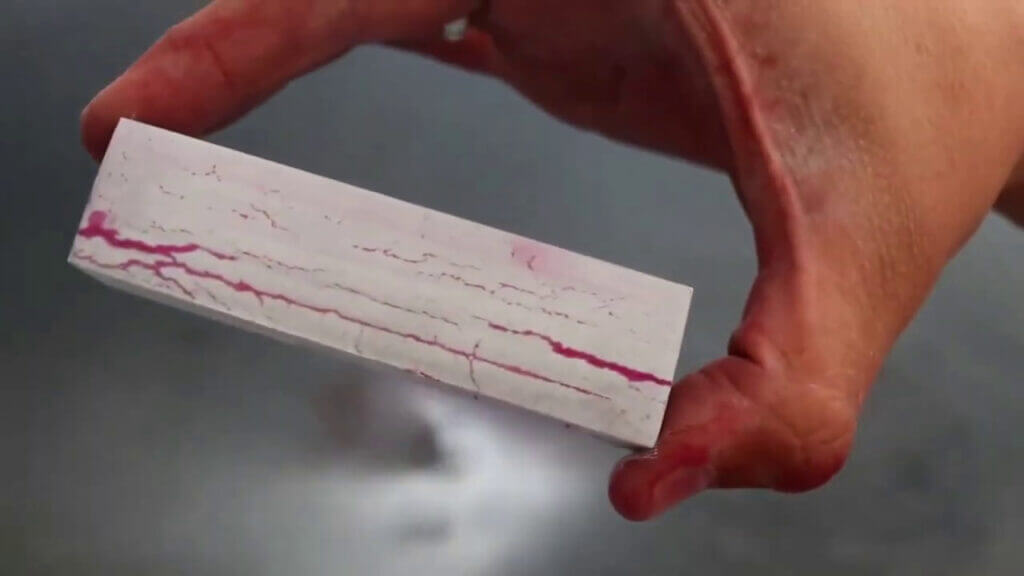

Technique for revealing surface flaws in solid materials by visual contrast of penetrant and developer.

Among the most challenging aspects of the job of a machinery professional or vibration analyst; is to decide whether a running machine should be taken out…

Non-invasive evaluation process to detect external corrosion in hydrocarbon transport systems.

Asset integrity helps anticipate risks and maintain operational reliability in complex industrial environments.

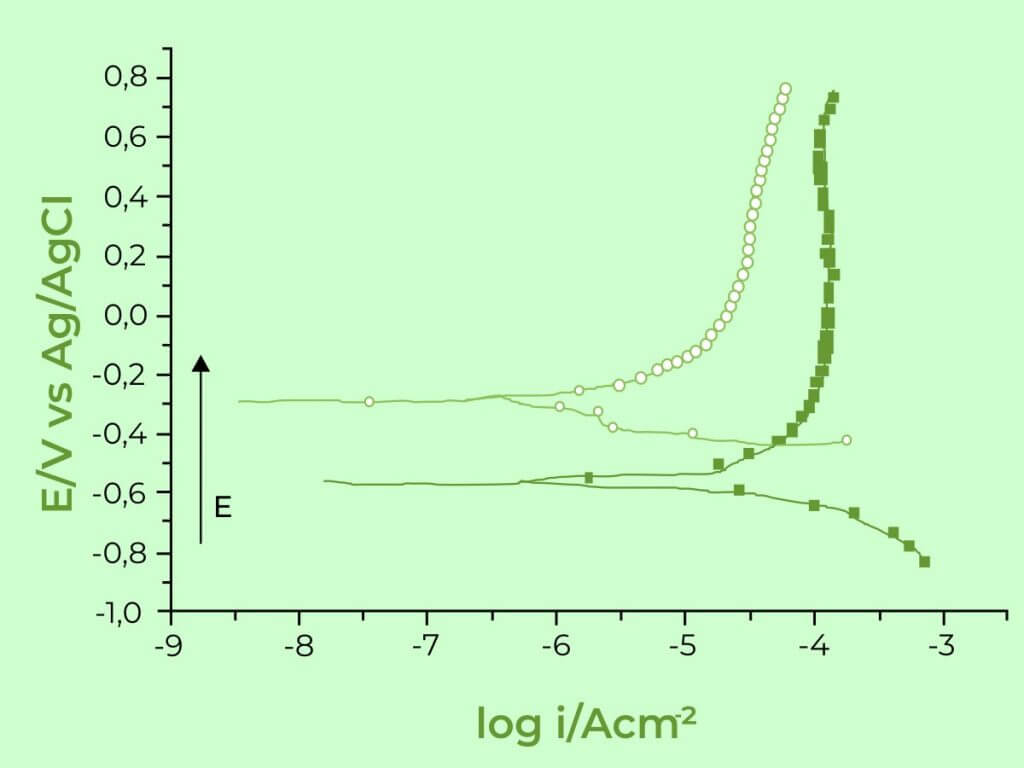

Ecological inhibitors reduce corrosion using natural, non-toxic compounds, minimizing environmental impact.

Introduction Industrial maintenance and reliability strategies Reliability Centered Maintenance (RCM) is a very powerful methodology that, when applied correctly, can lead to significant improvements in equipment…

Summary Brief introduction of technical aspects and basic notions of the Ultrasonic Guided Wave (UGW) technique. Introduction Guided wave technology is a non-destructive method that is…

Summary An exhibition is presented on the use of visual inspection tools in boiler pipes, external and internal, in order to identify and diagnose the integrity…