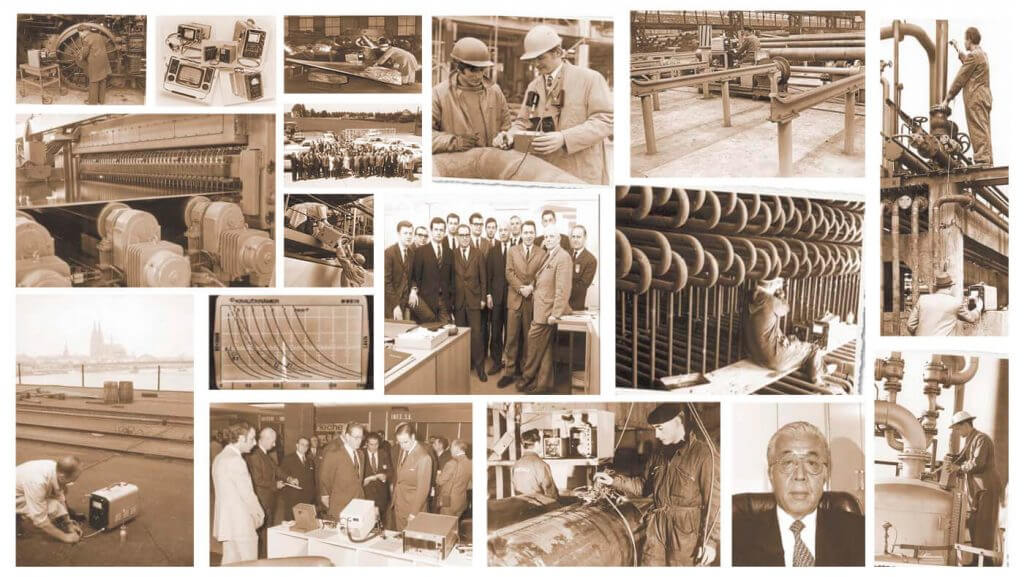

The Krautkrämer made history at the inspection

In 1946, the closure of the university continues and some of them remain in ruins, such as: the University of Cologne, where two brothers, one of…

In 1946, the closure of the university continues and some of them remain in ruins, such as: the University of Cologne, where two brothers, one of…

Continuing with this initiative that I have called "Corrosion Tourism, a trip to learn about the beauty and importance of corrosion in iconic structures", this time…

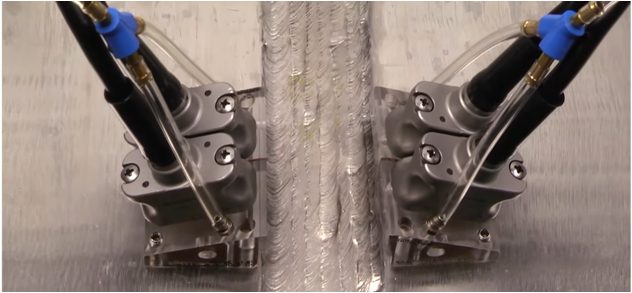

Inspection equipment is currently being developed based on new technologies in the detection of faults and corrosion damage. In this context, the company Waygate Technologies, through…

Una vista a los compuestos y tecnologías que prolongan la vida útil de estructuras expuestas a ambientes marinos agresivos.

XRF analysis ensures the correct identification of materials, fundamental in industries to guarantee the quality and operational reliability.

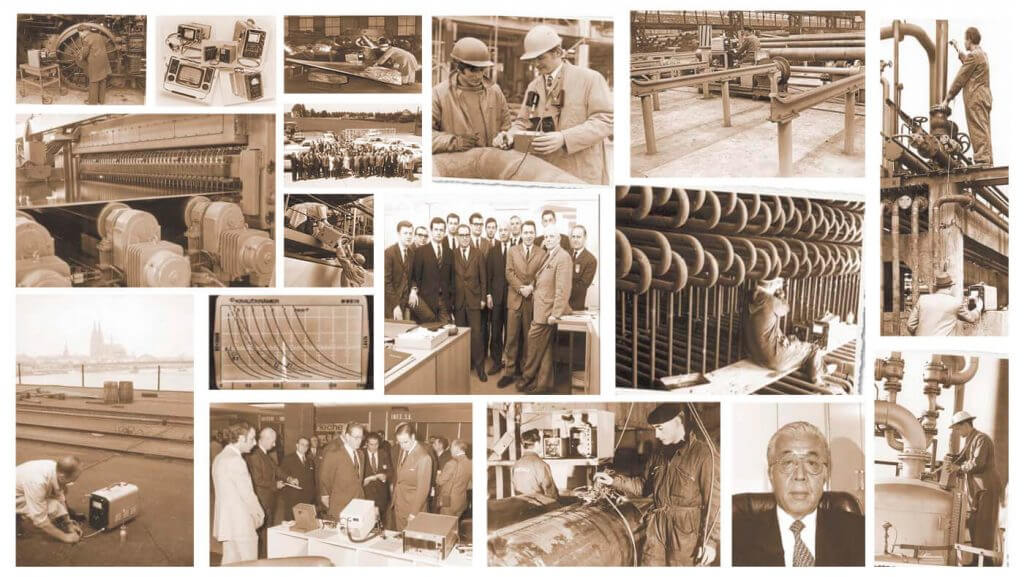

Researchers at the University of Massachusetts Institute of Technology (Massachusetts Institute of Technology) have developed a new polymerization process, generating a 2D two-dimensional polymeric material called…

Anniversary Inspenet: Knowledge and Professional Connection to the World Inspenet reaches its first year with a highly positive and extraordinary balance.

Corrosion affects different types of metals that are used in various industrial plants, generating failures, defects and causing leaks. Few methods currently exist to detect these…

Defining inspection priorities is part of the continuous monitoring of critical variables in operational components.

ColdBonding ensures reliable deck plate repairs in demanding maritime environments.

Ultrasonic and radiographic techniques allow the detection of discontinuities in austenitic stainless steel welds.

Visual inspection of oil facilities helps detect faults, prevent accidents, and effectively ensure operational continuity.