Application of X-ray diffraction in hydroelectric components

La técnica de difracción de rayos X permite caracterizar tensiones internas en materiales clave de infraestructuras hidroeléctricas.

La técnica de difracción de rayos X permite caracterizar tensiones internas en materiales clave de infraestructuras hidroeléctricas.

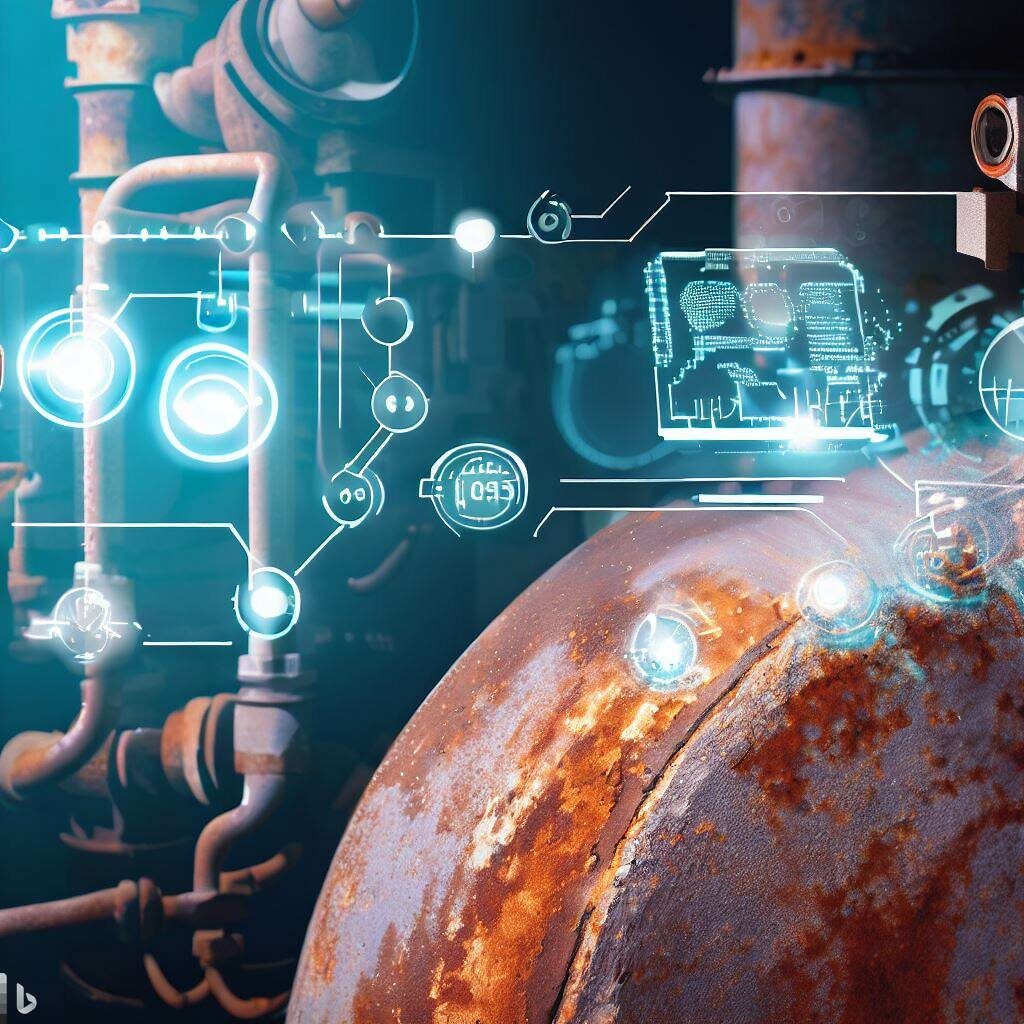

The IoT allows corrosion to be detected and managed in real time using specialized sensors and continuous data transmission.

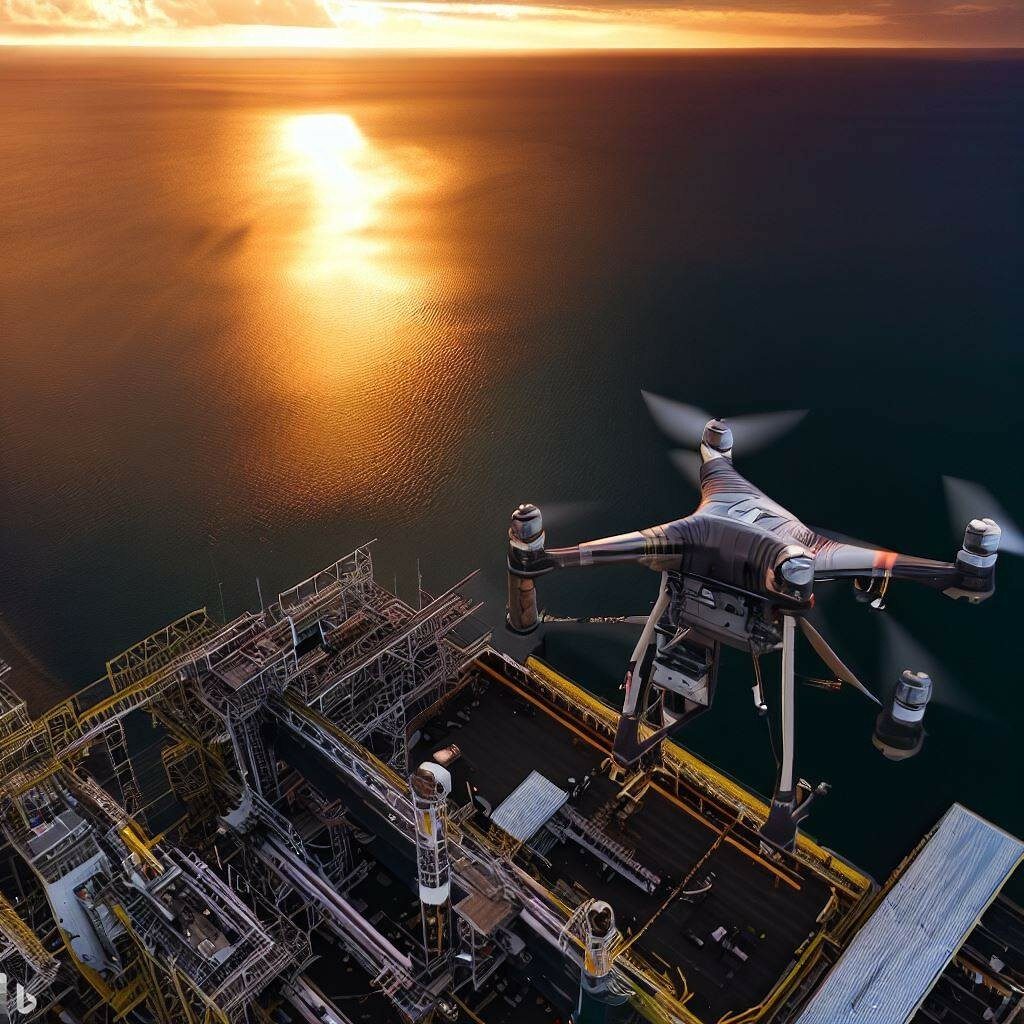

Drones and robots can detect corrosion in critical areas, improving precision and safety in industrial operations.

Corrosion in industry can have devastating consequences that can cause problems in structures and equipment. From material degradation to costly downtime, corrosion can significantly affect the…

Exploration of the mechanisms of degradation of structures in marine environments and their prevention.

Industrial challenges require innovative solutions such as NDT to ensure integrity without compromising functionality.

Vibration analysis in gas turbines is used to determine the operating and mechanical conditions of the equipment. A big advantage is that vibration analysis can identify…

Intelligent maintenance systems can be used to improve existing predictive, preventive and corrective maintenance programs, which provide functional, optimal and efficient support, allowing the implementation of…

Technical analysis of how non-destructive testing detects discontinuities without affecting the integrity of industrial components.

Industrial maintenance and inspection best practices on platforms and equipment are necessary to ensure asset safety and efficiency, as well as reduce downtime and repair costs.…

Risk assessment, predictive monitoring and aligned leadership as key pillars for a more reliable industrial operation.

Non Destructive Testing is a powerful tool for detecting failures in components of process units in the energy industry.