Robotic inspection in Oil & Gas: boosting operational efficiency

The Oil & Gas industry adopts robotic inspection to ensure safety, efficiency and structural integrity, responding to the pressure for increased energy demand.

The Oil & Gas industry adopts robotic inspection to ensure safety, efficiency and structural integrity, responding to the pressure for increased energy demand.

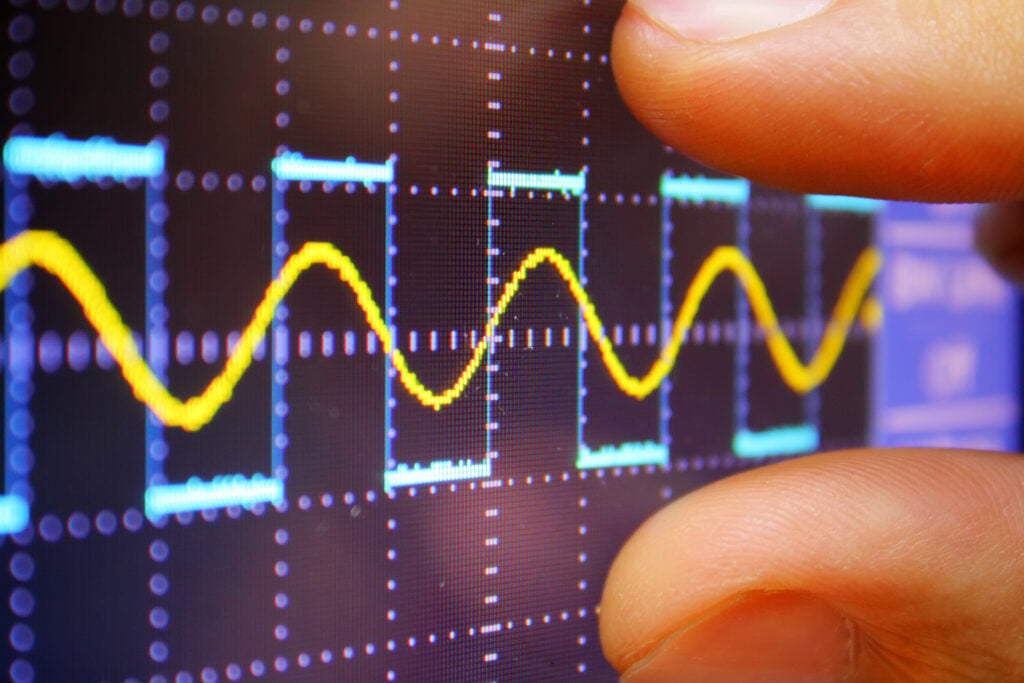

From manual analysis to digital systems, industrial ultrasound has become a key tool for maintenance and non-destructive diagnosis.

Ultrasonic sensor networks monitor corrosion in real time, detect failures and reduce operating costs, increasing industrial safety.

Inspenet, October 24, 2023. In the world of industrial inspection, the constant search for innovative technologies that allow a more precise and efficient evaluation of materials…

Artificial intelligence enables more efficient remote visual inspections, improving industrial safety, reducing costs and generating valuable visual analysis.

Identifies problems such as electrical interference and high soil resistivity in cathodic protection systems.

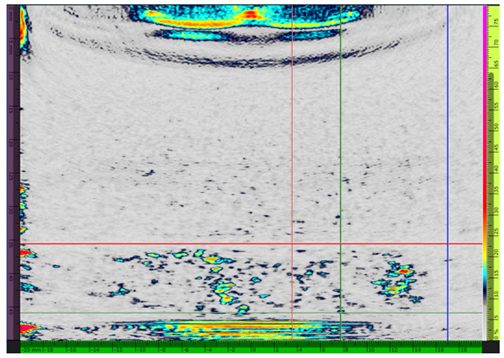

Identifying and assessing CUI requires reliable methods in the face of physical barriers and hidden conditions.

The design of the system depends on the coating, soil resistivity and type of structure to be protected.

SCC compromises metallic structures by combining mechanical stress and corrosion, requiring environmental control and appropriate material selection.

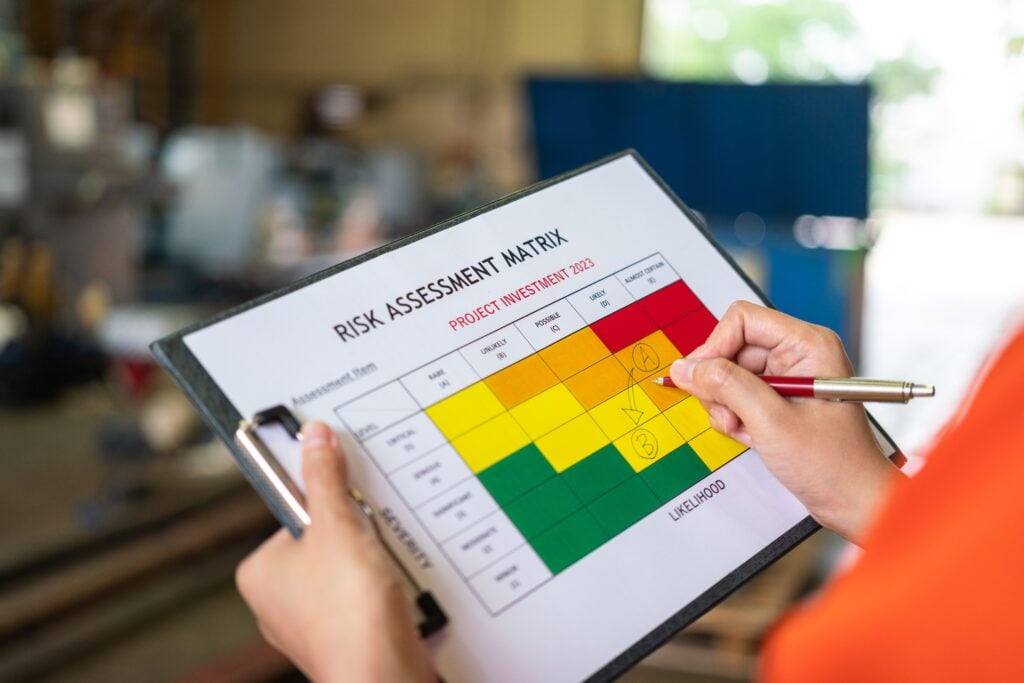

Review of real-life experiences with API RP 580, applied to optimize maintenance decisions and assess operational risks.

Marine corrosion is enhanced by environmental conditions that alter the electrochemical behavior of metallic materials.

Insulating gaskets are essential to maintain electrical separation and prevent interference in cathodic protection systems.