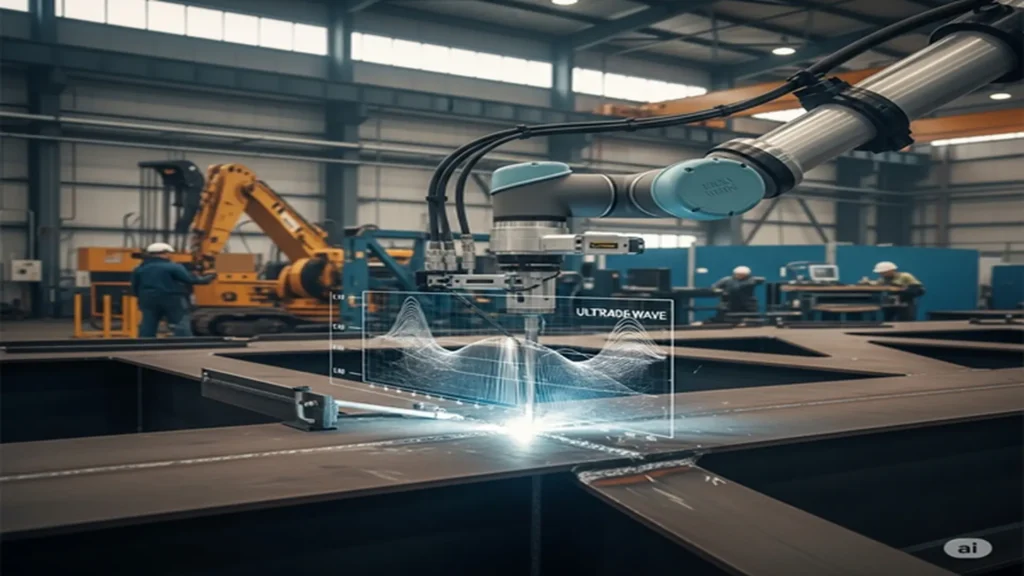

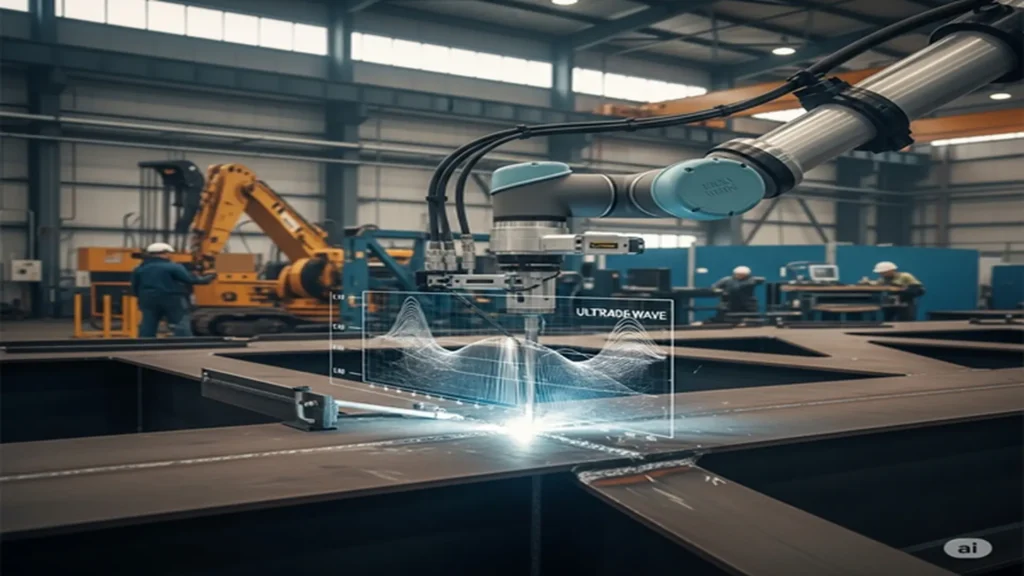

AI in Ultrasonic weld Inspection: Advanced detection

Artificial intelligence generates benefits in ultrasonic weld inspection by redefining its accuracy standards in the industry.

Artificial intelligence generates benefits in ultrasonic weld inspection by redefining its accuracy standards in the industry.

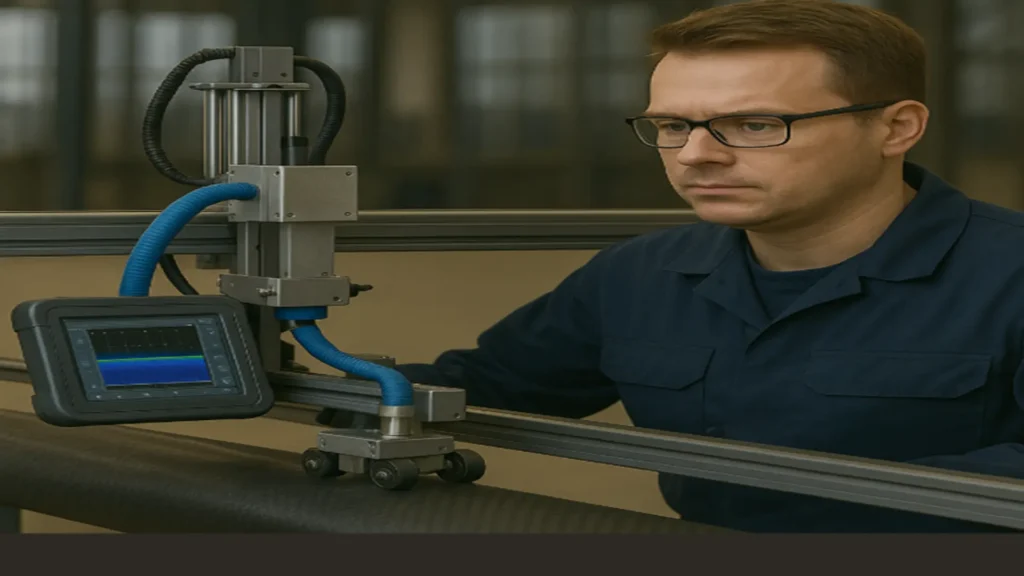

Data analysis strengthens Non-Destructive Testing (NDT), to manage defects with greater accuracy and anticipation.

Explore with Inspenet the steps for effective internal inspection in distillation towers. Learn key methods and enhance operational reliability.

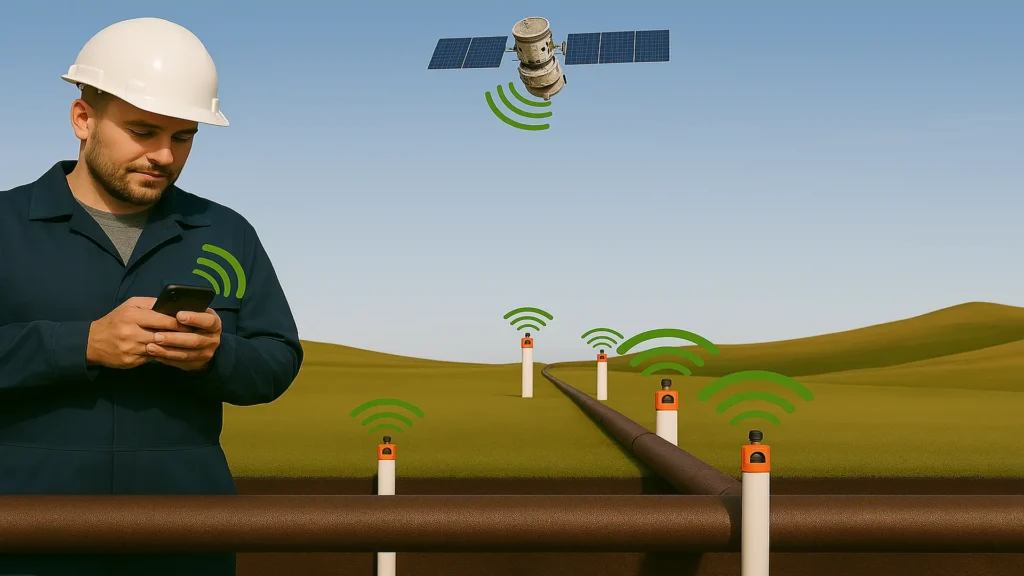

Remote monitoring of cathodic protection allows supervising systems without on-site inspection, detecting failures and optimizing the service life of metallic infrastructures.

Innovation in CFRP NDT with Ultrasonic Testing by Adaptive Segmentation

Optimize the inspection of complex surfaces and critical components with laser thermography, robotic systems and infrared sensors for accurate results.

INSPENET presents a technical analysis of the Pulsed Eddy Current method, an innovative solution to detect Corrosion Under Insulation (CUI) in height and critical pipelines.

Orienting future technicians on How to become a welder certified and highly skilled professional welder.

NDT allows the evaluation of concrete structures without altering them, thanks to its technological evolution, consolidating itself as a fundamental tool in today's industry.

AI transforms NDT by automating industrial inspection, improving accuracy, efficiency, and enabling predictive maintenance with human-machine collaboration.

Preserving heritage requires effective methods of evaluation, diagnosis and monitoring, where Non Destructive Testing (NDT) is crucial.

Operational modal analysis (OMA) has become a pivotal tool in the evolution of structural health monitoring, asset reliability, and predictive maintenance strategies.