Digital solutions for corrosion control in the oil & gas industry

Digital tools enable real-time monitoring, failure prediction, and optimized corrosion control strategies for industrial sectors.

Digital tools enable real-time monitoring, failure prediction, and optimized corrosion control strategies for industrial sectors.

The PCI technique allows the identification of HTHA damage in materials subjected to critical operating conditions.

Establishment of API technical standards and policies for safety, operational quality, and regulation in the hydrocarbon sector.

Piping circuit inspections ensure safety, efficiency and reliability, preventing failures with serious consequences on services, environment and safety.

Author: Ing. Mayuly Rodriguez, March 9, 2024. Atmospheric corrosion does not depend exclusively on the affected asset, since it develops under the influence of corrosive factors…

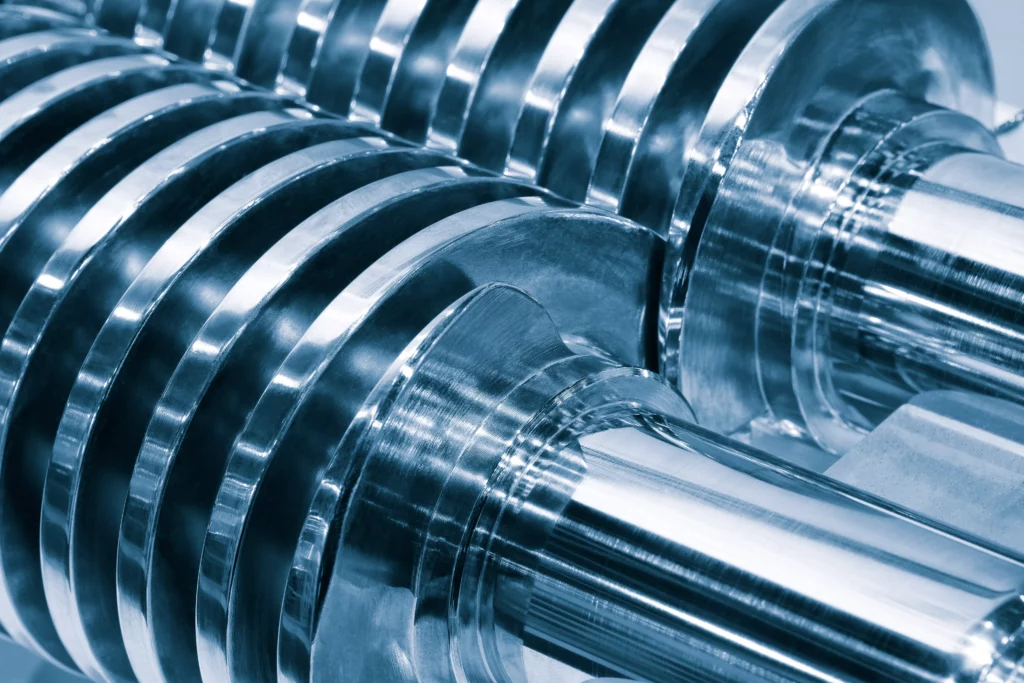

Author: Inspector. José López, 08 March 2024. Maximizing efficiency in rotating equipment is a fundamental element in various industries. Efficient rotating equipment leads to cost savings,…

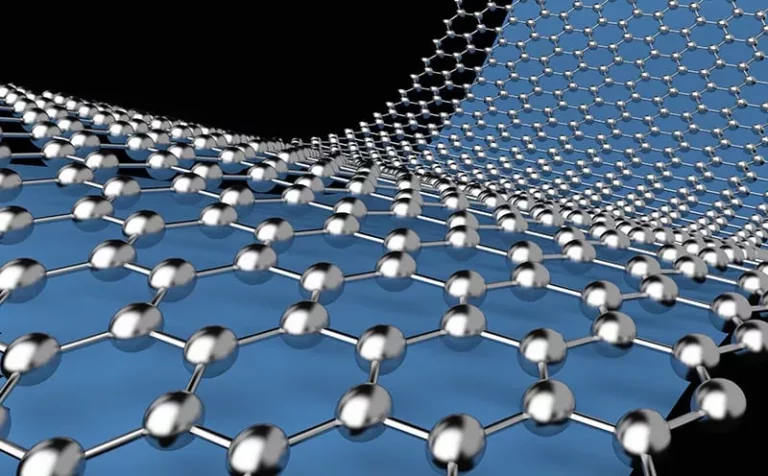

Graphene coatings significantly reduce corrosion in metallic structures, extending their useful life.

Advanced phased array ultrasound evaluation for corrosion inspection on smaller diameter lines.

Corrosion in the oil industry causes failures and high costs. AMPP helps prevent damage and maintain operational efficiency.

Caustic cracking compromises the integrity of steel; its prevention requires control of materials and operating conditions.

Technical review of the use of phased array ultrasound to evaluate flange defects within pressure and piping systems.

Author: Analyst. José López, 01 March 2024. A compressor is a device capable of increasing the pressure of a compressible fluid while reducing its volume. They…