Implementation of RCM by phases to ensure successful projects

RCM by phases allows high profits to be obtained with less time and resources, ideal for projects with constraints.

RCM by phases allows high profits to be obtained with less time and resources, ideal for projects with constraints.

Predictive maintenance reduces downtime and operating costs by anticipating failures through non-destructive analysis of equipment.

Providing knowledge on the selection, use and storage of coated electrodes in welding.

Improve underwater subsea welding techniques for safer and more efficient infrastructure maintenance.

Identifying and preventing failure modes in hydrocarbon storage tanks to ensure their integrity and safety.

Discover how to identify a good weld vs. bad weld, common defects and the most effective inspection techniques to ensure quality.

Application of NDT in the Foundry Industry: techniques, defects, properties, personnel selection and training.

Exploring the significance melting point of metal in selecting and using industrial materials.

Uncover the roles and challenges of MIC and MID, focusing on electrochemical processes and microbial impacts.

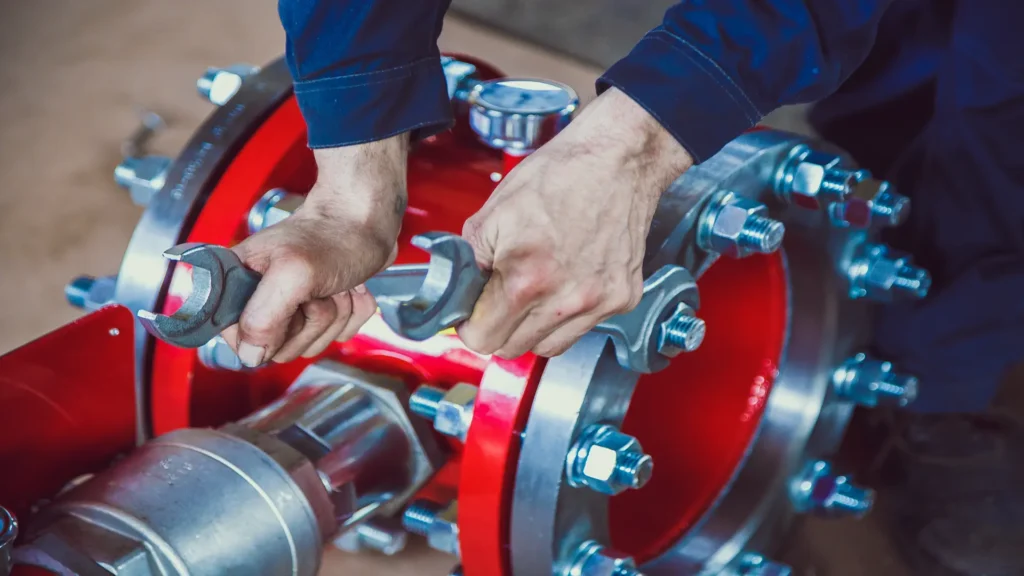

Describing the fundamentals of flange adjustment, emphasising the correct use of the bolt torque chart.

Analyzing zinc plating vs galvanized: Which method is more effective against corrosion?

Galvanic corrosion, a challenge in various industries, is prevented through proper material selection, strategic design, and effective cathodic protection.