Main types of NDT and their applications in the petroleum industry

The oil industry relies on NDT to maintain the integrity of equipment and structures, ensuring continuous operations.

The oil industry relies on NDT to maintain the integrity of equipment and structures, ensuring continuous operations.

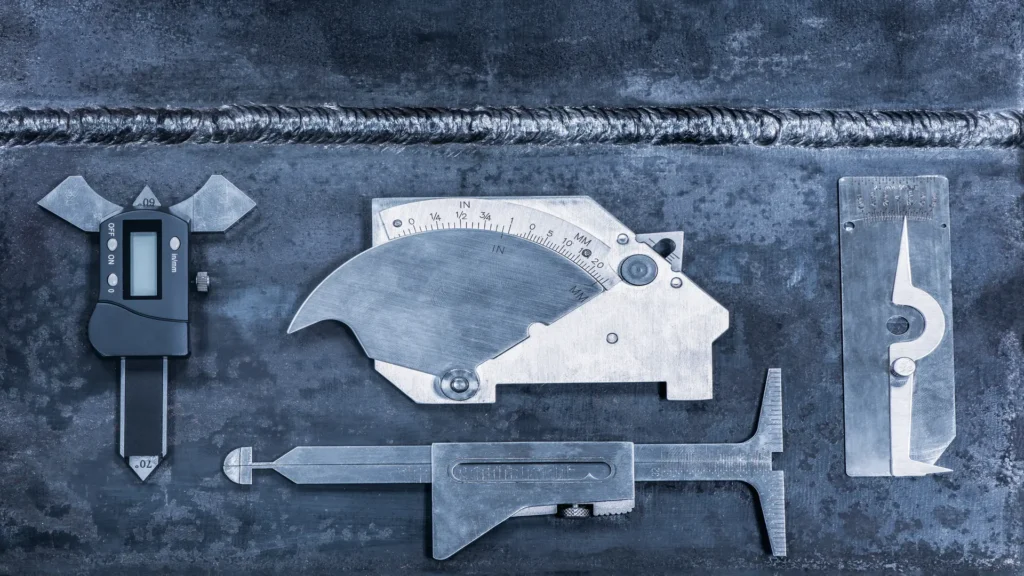

Ensure weld inspection accuracy and structural integrity using essential tools for flaw detection and measurement.

Understanding how MIG welding revolutionizes manufacturing processes with high efficiency, versatility, and automation.

Providing information on when to replace bearings in rotating equipment to ensure operational efficiency.

Introduction In the oil and gas industry, operational safety and efficiency are paramount. The concept of “Fitness For Service” (FFS) refers to evaluating the operational capacity…

Intelligent bearings revolutionize the industry by monitoring critical conditions in real time.

Promoting the integration of the circular economy in industrial dismantling.

This article focuses mainly on the steps to follow to monitor the efficiency of a cathodic protection system.

How NDT industry improves integrity, safety and operational efficiency in different sectors.

Analyze lap welding, describing its fundamentals, techniques, characteristics and industrial applications.

Knowledge of failure patterns is essential for designing maintenance policies.

Corrosion in buried pipelines is a critical issue for operational safety and efficiency in industries.