Explosion welding applied to cladding of dissimilar metals

Reliable and efficient technology for joining dissimilar metals using explosion welding in industrial cladding.

Reliable and efficient technology for joining dissimilar metals using explosion welding in industrial cladding.

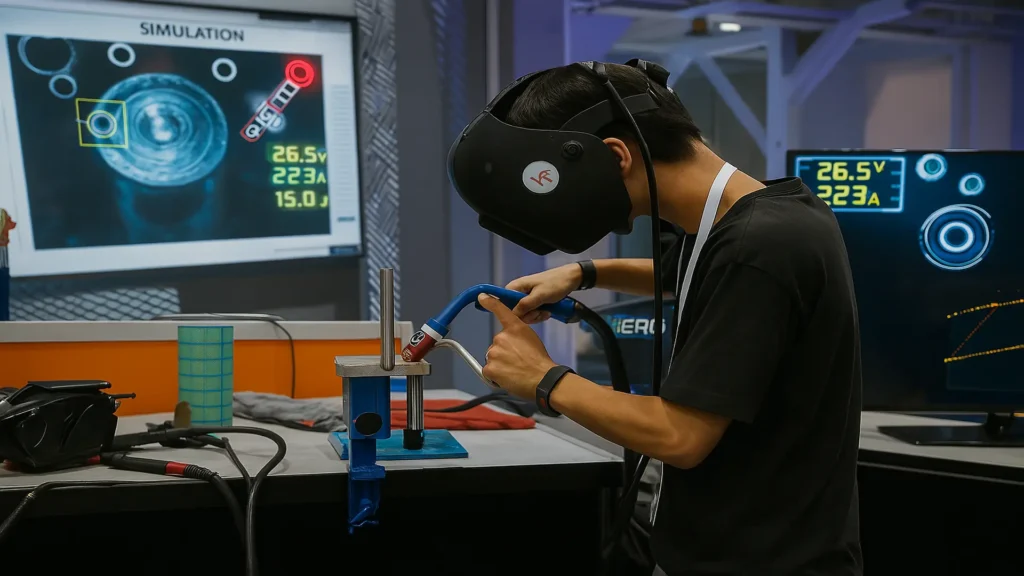

Inspenet reveals how VR simulators and digital platforms are reshaping welding training education through safety, efficiency, and next-gen certification pathways.

Friction stir welding (FSW) is a sustainable non-fusion metal joining process ideal for aluminum, copper, titanium and other metals.

Explore with Inspenet the steps for effective internal inspection in distillation towers. Learn key methods and enhance operational reliability.

Orienting future technicians on How to become a welder certified and highly skilled professional welder.

Positive material identification avoids critical errors by validating specifications in the field, improving quality control and operational efficiency.

Butt welding, used in many sectors, guarantees strong and safe metal joints, adapting to modern requirements through constant technical innovation.

Techniques, innovations, and challenges in nuclear welding for power plants: a focus on safety and quality.

The borescope enables non-destructive internal inspections in difficult areas, optimizing industrial maintenance and avoiding costly disassembly of key equipment.

Sandblasting is a surface cleaning method that, in line with current environmental regulations, incorporates sustainable alternatives in its application.

Highlighting the history of the American Welding Society (AWS), its impact on the industry and its leadership in welding.

Review and analyze how coating inspection protects your industrial assets, optimizes costs and improves operational safety.