Industrial painting: Cost savings through planned maintenance

The planned maintenance of industrial paint is essential for the corrosion protection of assets.

The planned maintenance of industrial paint is essential for the corrosion protection of assets.

Brass dezincification is a critical problem in materials exposed to aggressive environments, affecting their structural strength and functionality over time.

Flash rust is an immediate surface oxidation that affects the adhesion of coatings and reduces metal service life.

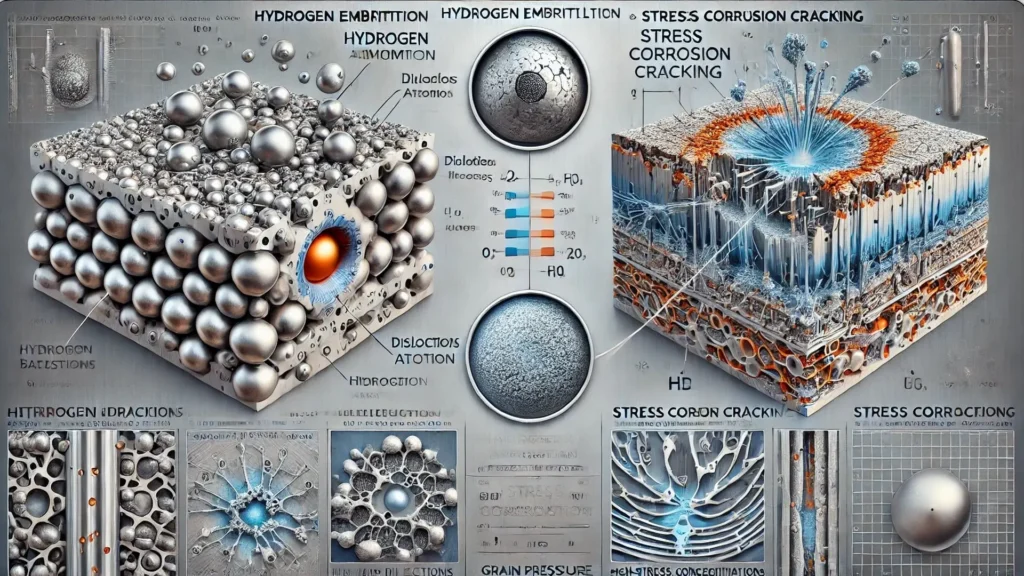

Distinguishing between hydrogen embrittlement and SCC allows for the assessment of mechanical and environmental risks in metals exposed to loads or corrosives.

FRP coatings improve the strength and durability of industrial tanks, protecting them against corrosion and aggressive chemical agents.

Powder coating creates a protective and decorative coating without solvents, reducing VOC emissions and material waste.

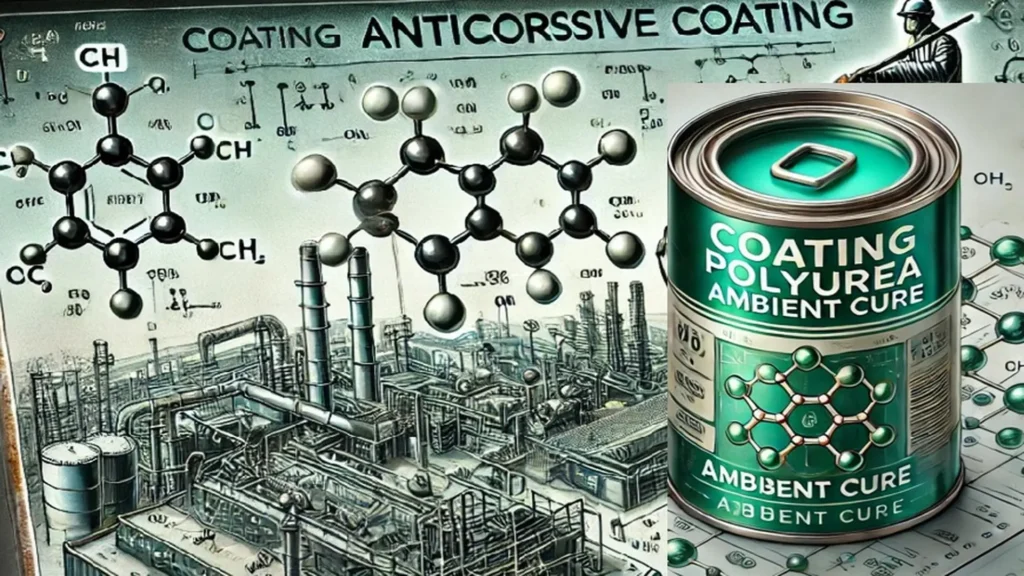

The future of green polyurea technology drives sustainable, high-performance solutions in the industry.

Used in various industries, pyrophoric materials burn spontaneously on contact with air, requiring specialized handling.

MIC corrosion deteriorates metals in industrial sectors by microorganisms, with electrical (EMIC) and chemical (CMIC) mechanisms that compromise their safety and durability.

The steel industry produces steel through advanced processes, driving global development in infrastructure, transportation, technological innovation and sustainability.

Explaining how cavitation corrosion generates pitting and fracture in hydraulic and mechanical equipment, affecting its useful life.

Hydrogen embrittlement is a phenomenon that weakens the mechanical properties of materials exposed to hydrogen.