Structural integrity and its importance in asset management

Structural integrity ensures safety, optimizes assets and prolongs service life in the industry.

Structural integrity ensures safety, optimizes assets and prolongs service life in the industry.

As a critical technology, the mechanical seal prevents leakage under extreme conditions, improving the reliability of rotating equipment such as pumps, compressors and turbines.

In the era of Industry 4.0, industrial telemetry has become a mainstay in monitoring rotating equipment such as turbines and compressors.

Subsea pipeline protection is essential for the safe and continuous operation of offshore power grids, ensuring the integrity of these critical systems.

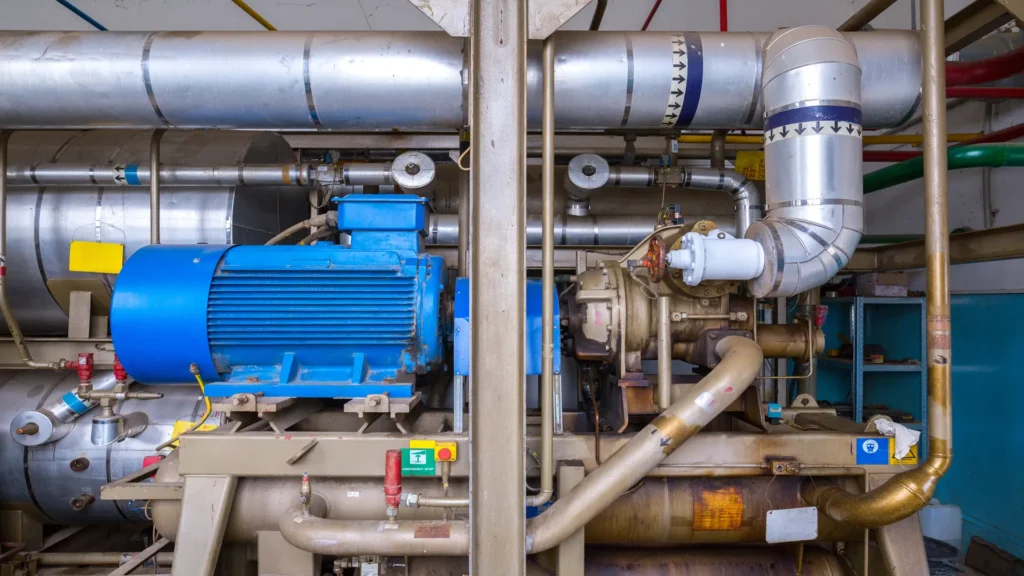

Compressors are crucial in industrial operations, increasing the pressure of gases for transport, power generation and process automation.

Key types, functions and API standards for oil storage tanks in safe and regulated industrial operations.

Industrial refrigeration systems are essential in sectors such as food, pharmaceuticals, chemicals and petrochemicals.

Analyzing the role of the mud pump in drilling, and how technological innovations impact well efficiency, operability, and safety.

Technical analysis of the rotary kiln: operation, models, industrial uses, and innovations in thermal design.

Remote inspection is already a reality in above ground storage tanks. Robotics, drones and API 653 regulations in a single article.

Settlement in a storage tank compromises its structural integrity, affecting the safety, operation and life of the system.

Cavitation is a phenomenon that affects the performance of hydraulic systems, characterized by the formation and collapse of vapor bubbles.